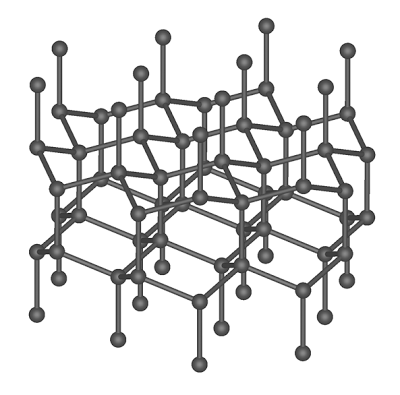

In the case of lonsdaleite [hexagonla diamond], compression mechanism also caused bond-flipping, yielding an indentation strength of 152 GPa, which is 58 percent higher than the corresponding value of diamond. viaPhysorg.com

Under large compressive pressures, w-BN [wurtzite boron nitride] increases its strength by 78 percent compared with its strength before bond-flipping. The scientists calculated that w-BN reaches an indentation strength of 114 GPa (billions of pascals), well beyond diamond’s 97 GPa under the same indentation conditions.

“Lonsdaleite is even stronger than w-BN because lonsdaleite is made of carbon atoms and w-BN consists of boron and nitrogen atoms,” Chen explained. “The carbon-carbon bonds in lonsdaleite are stronger than boron-nitrogen bonds in w-BN. This is also why diamond (with a cubic structure) is stronger than cubic boron nitride (c-BN).”

By showing the underlying atomistic mechanism that can strengthen some materials, this work may provide new approaches for designing superhard materials. As Chen explained, superhard materials that exhibit other superior properties are highly desirable for applications in many fields of science and technology.

“High hardness is only one important characteristic of superhard materials,” Chen said. “Thermal stability is another key factor since many superhard materials need to withstand extreme high-temperature environments as cutting and drilling tools and as wear, fatigue and corrosion resistant coatings in applications ranging from micro- and nano-electronics to space technology. For all carbon-based superhard materials, including diamond, their carbon atoms will react with oxygen atoms at high temperatures (at around 600°C) and become unstable. So designing new, thermally more stable superhard materials is crucial for high-temperature applications. Moreover, since most common superhard materials, such as diamond and cubic-BN, are semiconductors, it is highly desirable to design superhard materials that are conductors or superconductors. In addition, superhard magnetic materials are key components in various recording devices.”

More information: Pan, Zicheng; Sun, Hong; Zhang, Yi; and Chen, Changfeng. “Harder than Diamond: Superior Indentation Strength of Wurtzite BN and Lonsdaleite.” Physical Review Letters 102, 055503 (2009).

FURTHER READING OTHER HARDER THAN DIAMOND MATERIALS

Ultrahard fullerite (C60) is a form of carbon found to be harder than diamond, and which can be used to create even harder materials. A Type IIa diamond (111) has a hardness value of 167±6 gigapascals (GPa) when scratched with an ultrahard fullerite tip. A Type IIa diamond (111) has a hardness value of 231±5 GPa when scratched with a diamond tip; this leads to hypothetically inflated values.

Ultrahard fullerite can be made into Aggregated diamond nanorods. aggregated diamond nanorods have a modulus of 491 gigapascals (GPa), while a conventional diamond has a modulus of 442 GPa. ADNRs are also 0.3% denser than regular diamond.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.