Ad Support : Nano Technology Netbook Technology News Computer Software

These different fabrication approaches are connected. Microspheres and nanospheres form the building blocks of the Voxel fabbing concept and having access to smaller spheres increases the resolution of voxel fabbing. Also, the spheres can be used to make nanopillars of different sizes as shown in the nanosphere lithography method. Those nanopillars can be used to imprint uniform holes. The holes can be used to extrude columns. Combined there is a wide range of manufacturing processes that can be produced. There is also cheap laser cutting.

1. The concept of Voxel fabbing is described as an approach to digital matter and rapid assembly.

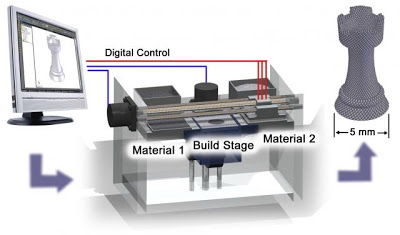

Imagine a desktop fabricator capable of making perfectly repeatable, arbitrary, multi material 3D objects with microscale precision. The objects would be composed of millions or even billions of small physical building blocks (voxels). Some building blocks could be hard, some could be soft. Some could be red, others green or blue. Some could be conductive and others could perform computation or store energy. Some could even be sensors and others actuators, and so on and so forth. With a relatively small repertoire of building block types and a rapid assembler, one could assemble a relatively large variety of machines at high resolution.

Voxels are the building blocks for making things. A rapid assembler will select and organize these Voxels and build them layer by layer into an object. Because you can select different Voxels you can give your object lots of different material properties, even properties that have been impossible. Voxels will then be true digital materials.

Digital manufacturing is inspired from biology, where DNA, amino acids, and proteins all illustrate systems where a digital structure is formed from a discreet number of aligned, fundamental building blocks. Since the voxels must self-align and interlock with those around them, the overall accuracy is determined by the individual voxels, which can be made very precisely using microfabrication techniques. This phenomenon is analogous to a child (with ~1mm finger positioning accuracy) assembling a Lego(TM) structure with 5 micron precision. Inherent to the success of this technology is a fabricator that can rapidly assemble millions of voxels in a parallel, top-down approach

Just like inkjet printers scan continuously and deposit drops of ink into paper, the VoxJet deposits physical voxels (or 3D pixels) to create 3D digital matter. This research platform is capable of depositing a 3D lattice of small spheres at a continuous deposition rate of ten spheres per second. Up to three materials may be combined in any configuration. An integrated binder deposition system and non-contact laser feedback system enable robust, repeatable results.

The voxjet has been used to demonstrate fully recyclable multi-material 3D printing. In this process, voxels of multiple materials are printed and bound together by a reversible binder. When it’s no longer wanted, the bonds holding the spheres together are reversed (in this case using water-soluble glue), and the individual spheres are reclaimed and fed back into the machine.

A second technology based on the paradigm of laser printing is also being developed, which has the ability to place an entire layer of voxels simultaneously.

2. In 2008, there is a paper – Large areas of periodic nanoholes perforated in multistacked films produced by lift-off (Journal of Vacuum Science Technology) A low-cost and high-throughput method—nanosphere photolithography, for generating periodic subwavelength holes in metals/dielectrics. By combining the self-assembled and focus properties of micro-/nanospheres, the authors utilized the sphere arrays as lenses to produce large areas of nanopillars with a strong undercut in negative photoresist. Using lift-off with the nanopillars of photoresist, the authors demonstrate a large area of uniform nanoholes of as small as 50 nm in diameter at the bottom of ~160 nm thick metal.

4. UP! is a portable 3D printer that was announced for sale earlier this month. PP3DP.com, the company behind the printer, is selling the first 100 UP! printers for $1,500 — 50% off the standard rate

5. You can quickly and easily make paper prototypes with a CNC paper cutter.

* Silhouette SD is a basic, inexpensive model made by Graphtec ($250-300)

* Craftrobo by Graphtec for $1000

* Klic-n-Kut for $600-$1200 depending on model

If you liked this article, please give it a quick review on Reddit, or StumbleUpon. Thanks

Supporting Advertising

Business Success

How to Make Money

Executive Jobs

Paid Surveys

Thank You

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.