Quantum Materials Corporation and the Access2Flow Consortium of the Netherlands today announce that continuous production of Tetrapod Quantum Dots has been achieved using its proprietary micro reactor technology. Processes for producing quantum dots and tetrapod-shaped quantum dots of various sizes delivers on the promise of this technology to tailor-make material at commercial quantities for a variety of emerging applications such as Solterra Renewable Technologies’ solar panels, displays, lighting, and medical diagnostics. Production is on track to increase by 70,000 times from 10 grams per week to 100 kg per day.

Currently, one of the lab scale reactors is capable of producing approximately 10 grams of quantum dots per week. Commercially relevant, the inherent design now allows for large-scale parallel modules to achieve target production rates of multiple kilograms per day, in a regulated, optimized system.

The goal is to achieve a production rate of 100kg per day with a 95% or greater yield.

Rice University Quantum Dot Synthesis

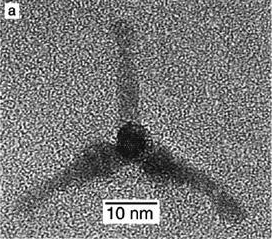

Dr. Michael S. Wong’s lab at William Marsh Rice University invented a simplified synthesis using greener fluids in a moderate temperature process producing same-sized QD particles, in which more than 95 percent are tetrapods; where previously even in the best recipe less than 50 percent of the prepared particles were all same size and tetrapods. These highly efficient tetrapod QD are available across the entire light wavelength from UV to IR spectra and very narrow bandwidth is common. Selectivity of arm width and length is very high allowing different characteristics to be emphasized. Capping with shells and dyes adds desired properties. A custom mixture of quantum dots tuned to optimal wavelengths is easy to create, and projects will have the advantage of unprecedented flexibility and quantities for determining the optimal quantum dot without the time, expense and poor quality of batch synthesis methods.

Furthermore, the Rice process uses much cheaper raw materials and fewer purification steps. A positively charged molecule called cetyltrimethylammonium bromide provides this dramatic improvement in tetrapod manufacture. This compound, found in some shampoos, also is 100 times cheaper than alkylphosphonic acids currently used and is far safer, further simplifying the manufacturing process.

Access2Flow QD Mass-Production

Access2Flow continuous flow micro-reactor processing will enable us to scale up the manufacture to our goal of 100kg/day production without loss of quality. Through QMC research and development in conjunction with A2F, we have made improvements on the process which are an integral part of our intellectual property contributed to our Joint Venture and other partnerships. We will be the first to mass produce the highest quality quantum dots at the lowest cost on the market using readily available, non-REE materials.

The Access2Flow continuous flow micro-reactor maintains the synthesis process precise and narrow wavelength uniformity. The quality and quantity of our tetrapod quantum dots have exceeded our requirements and far exceed what is available on the market today. Due to the simplicity of our scale-up to mass production, we believe we could provide last year’s display industry’s total consumption of QD in one month’s production.

Both full-scale quantum dot manufacturing and quantum dot based thin-film photovoltaic solar panel facilities can be developed today with available technologies

Many discoveries have literally been held back by the difficulty in manufacturing quantum dots, the lack of quality and uniformity of quantum dots, and the corresponding high cost, with the current average cost of quantum dots running being between $2500 and $6000/gram. This technology removes the roadblock from widespread adoption of the quantum dot as a basic building block of technology and services much like the silicon chip that has ubiquitously advanced corporate function and consumer lifestyles worldwide.

According to research group BCC Research, the 2010 global market for quantum dots was estimated $67 million in revenues, and is projected to grow quickly over the next 5 years at greater than 50% per year reaching almost $670 million by 2015.

Quantum dots refer to one of several promising materials niche sectors that recently have emerged from the burgeoning growth area of nanotechnology. Quantum dots fall into the category of nanocrystals, which also includes quantum rods and nanowires. As a materials subset, quantum dots are characterized by particles fabricated to the smallest of dimensions from only a few atoms and upwards. At these tiny dimensions, they behave according to the rules of quantum physics, which describe the behavior of atoms and sub atomic particles, in contrast to classical physics that describes the behavior of bulk materials, or in other words, objects consisting of many atoms.

Quantum Dots measure near one billionth of an inch and are a non-traditional type of semiconductor. They can be used as an enabling material across many industries and are unparalleled in versatility and flexible in form.

Rice University Quantum Dot Synthesis

Dr. Michael S. Wong’s lab at William Marsh Rice University invented a simplified synthesis using greener fluids in a moderate temperature process producing same-sized QD particles, in which more than 95 percent are tetrapods; where previously even in the best recipe less than 50 percent of the prepared particles were all same size and tetrapods. These highly efficient tetrapod QD are available across the entire light wavelength from UV to IR spectra and very narrow bandwidth is common. Selectivity of arm width and length is very high allowing different characteristics to be emphasized. Capping with shells and dyes adds desired properties. A custom mixture of quantum dots tuned to optimal wavelengths is easy to create, and projects will have the advantage of unprecedented flexibility and quantities for determining the optimal quantum dot without the time, expense and poor quality of batch synthesis methods.

Furthermore, the Rice process uses much cheaper raw materials and fewer purification steps. A positively charged molecule called cetyltrimethylammonium bromide provides this dramatic improvement in tetrapod manufacture. This compound, found in some shampoos, also is 100 times cheaper than alkylphosphonic acids currently used and is far safer, further simplifying the manufacturing process.

Access2Flow QD Mass-Production

Access2Flow continuous flow micro-reactor processing will enable us to scale up the manufacture to our goal of 100kg/day production without loss of quality. Through QMC research and development in conjunction with A2F, we have made improvements on the process which are an integral part of our intellectual property contributed to our Joint Venture and other partnerships. We will be the first to mass produce the highest quality quantum dots at the lowest cost on the market using readily available, non-REE materials.

The Access2Flow continuous flow micro-reactor maintains the synthesis process precise and narrow wavelength uniformity. The quality and quantity of our tetrapod quantum dots have exceeded our requirements and far exceed what is available on the market today. Due to the simplicity of our scale-up to mass production, we believe we could provide last year’s display industry’s total consumption of QD in one month’s production.

Both full-scale quantum dot manufacturing and quantum dot based thin-film photovoltaic solar panel facilities can be developed today with available technologies

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.