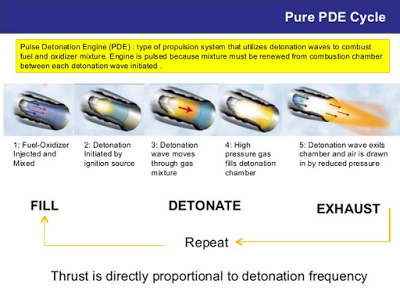

A pulse detonation engine, or “PDE”, is a type of propulsion system that uses detonation waves to combust the fuel and oxidizer mixture. The engine is pulsed because the mixture must be renewed in the combustion chamber between each detonation wave initiated by an ignition source. Theoretically, a PDE can operate from subsonic up to a hypersonic flight speed of roughly Mach 5. An ideal PDE design can have a thermodynamic efficiency higher than other designs like turbojets and turbofans because a detonation wave rapidly compresses the mixture and adds heat at constant volume.

To date, no practical PDE has been put into production, but several testbed engines have been built and one was successfully integrated into a low-speed demonstration aircraft that flew in sustained PDE powered flight in 2008.

There is also work to develop pulse detonation turbines for higher efficiency power generation. Pratt and Whitney is developing a new combustor for gas turbine engines that uses shockwaves for more efficient combustion through a process known as continuous detonation. GE has also been working on pulse detonation.

Airbus is researching the continuous detonation wave engine. The continuous detonation wave engine (CDWE) is a radical new technology which could offer significantly more efficient and capable propulsion systems for civil aircraft – with expectations to deliver substantial fuel savings while reducing emissions.

When fitted to a conventional jet engine, CDWE technology offers to transform overall engine performance and simplify its design by using detonation waves to combust the fuel and oxidizer mixture. Theoretically, this system can operate from subsonic up to a hypersonic flight speed of roughly Mach 5, with higher efficiency than designs such as turbojets and turbofans. This is because a detonation wave rapidly compresses the mixture and adds heat at constant volume – providing a thermal efficiency improvement of approximately 25 percent.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.