Tesla Motors is on track for initial lithium-ion battery production at the Gigafactory by the end of 2015 and significant production for existing Tesla models in 2016. Of course, Tesla intends to get production up to 500,000 battery packs a year by 2020, but it is going to complete the Gigafactory and ramp up production in phases.

Pacific Crest Securities analyst Brad Erickson toured Tesla’s Fremont factory, and he estimated that the Tesla Model X production line has 3–4 times more robots than the Model S production line.

Tesla is relying on the economies of scale of the huge factory to allow it to sell the Model 3 at a base price of $35,000 before incentives.

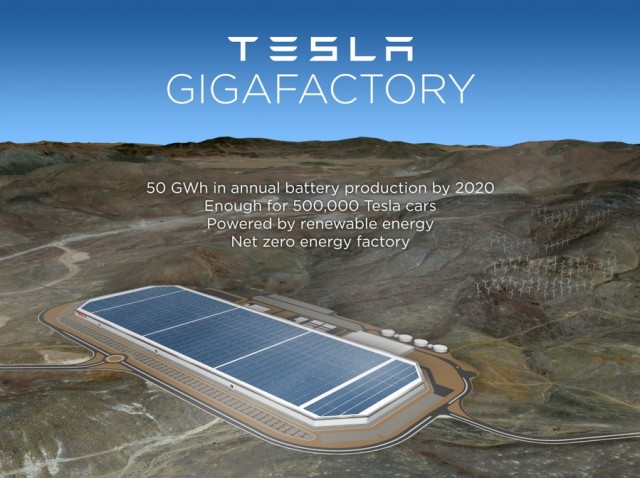

Gigafactory picture from Feb, 2015

Author Randy Carlson predicts three versions of the Model 3.

* 344: Entry-level, single-motor, rear-wheel drive version, with a base price of $35,000, EPA range of 220 miles from a 44-kWh battery, and 0-to-60-mph time of 5.6 seconds

* 366D: Dual-motor AWD standard version with an EPA range of 320 miles from a 66-kWh battery. 0-60 time 4.7 seconds, price $44,000

* P366D: 340-hp performance version with dual motors, AWD, a 300-mile EPA range, and 0-to-60 time of 3.1 seconds; priced with leather and a luxury interior at $60,000

It is expected that the model 3 will have the outside volume similar to the BMW 3 series but because of the smaller electric motor and electric car advantages will have more passenger and cargo space inside.

Tesla and its cell partner Panasonic will use a silicon-graphene anode in place of the current cell’s graphite anode

The cost per kilowatt-hour of such a cell, produced in the Gigafactory, would be cut in half, Carlson predicts. Energy density would increase by 29 percent, from the current 265 watt-hours per kilogram to 343 Wh/kg.

A conservative estimate from Carlson (including improved inverter and other components) expects the entry-level 344 version, at $35,000, will produce a 10 percent profit margin. A loaded P366D would deliver a 30-percent profit margin.

Carlson estimates the cost to build the Model 344’s 44-kWh battery at $6,918.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.