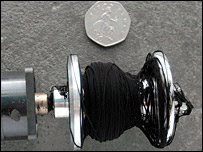

Carbon nanotube fiber on spindle from Alan Windle group. 2007 picture

The Cambridge team is making about 1 gram of the high-tech material per day, enough to stretch to 18 miles in length. “We have Nasa on the phone asking for 144,000 miles of the stuff, but there is a difference between what can be achieved in a lab and on an industrial level,” says Alan Windle, professor of materials science at Cambridge University, who is anxious not to let the work get ahead of itself.

How long is the carbon nanotube fiber ?

How strong is this carbon nanotube fiber ?

We will update when information becomes available.

Space Elevator blog also discusses this new information but also does not have specifics yet.

BBC had coverage on Windle’s work back in 2007

The fibre created in Cambridge is very strong, lightweight and good at absorbing energy in the form of fragments travelling at very high velocity.

Our fibre is up there with the existing high performance fibres such as Kevlar”, said Professor Windle.

But he added: “We’ve seen bits that are much better than Kevlar in all respects”.

A hydrocarbon feedstock, such as ethanol, is injected into the furnace along with a small amount of iron-based catalyst.

Inside the furnace, this feedstock is broken down into hydrogen and carbon. The carbon is then chemically “re-built” on particles of iron catalyst as long, thin-walled nanotubes.

To the eye, this “elastic smoke” looks a bit like an ever-expanding dark “sock”.

To begin winding it up, a rod is inserted into the furnace from below to grab one end of the sock and yank it down. This stretches the sock into a filament that can be wound up continuously on a reel.

The researchers are currently seeking funds to investigate whether the method can be upgraded from a laboratory to an industrial process.

Cambridge Enterprise Limited, the commercialisation office of the University of Cambridge, filed an initial patent application in July 2003.

It has now granted a licence to Q-Flo Limited, a university spin-out company, which will exploit the technology.

Alan Windle’s website at Cambridge University

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.