Researchers assessed the feasibility, implications, limitations, and enablers of annually producing 90 billion gallons of ethanol — sufficient to replace more than 60 billion of the estimated 180 billion gallons of gasoline expected to be used annually by 2030. Ninety billion gallons a year exceeds the U.S. Department of Energy’s goal for ethanol production established in 2006.

The 90 Billion Gallon Study assumes 75 billion gallons would be ethanol made from nonfood cellulosic feedstocks and 15 billion gallons from corn-based ethanol. The study examined four sources of biofuels: agricultural residue, such as corn stover and wheat straw; forest residue; dedicated energy crops, including switchgrass; and short rotation woody crops, such as willow and poplar trees. It examines the costs of producing, harvesting, storing and transporting these sources to newly built biorefineries.

A 4 page pdf executive summary describes the 90 billion gallon biofuel deployment plan.

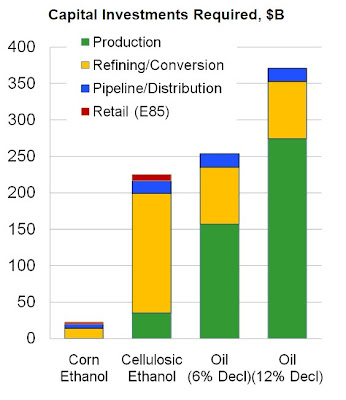

Biofuels capital expenditures necessary to achieve 60 billion gallons per year [90 billion gallons of biofuel is energy equivalent to 60 billion gallons of gasoline] of installed production capacity are on the order of $250 billion.

This study demonstrates that cellulosic biofuels can compete with oil at $90/bbl based on the following assumptions:

1) Average conversion yield of 95 gallons per dry ton of biomass

2) Average conversion plant capital expenditure of $3.50 per installed gallon of nameplate capacity

3) Average farm-gate feedstock cost of $40 per dry ton

Sensitivity analyses varying these assumptions individually gave potential cost competitiveness with oil priced at $70/bbl to $120/bbl

Using a newly developed tool known as the Biofuels Deployment Model, or BDM, Sandia researchers determined that 21 billion gallons of cellulosic ethanol could be produced per year by 2022 without displacing current crops.

Large-scale cellulosic biofuel production could be achieved at or below current water consumption levels of petroleum fuels from on-shore oil production and refining.

Sandia’s analysis also included land use, water availability, energy used to produce cellulosic biomass, transportation of feedstocks and other potential leverage points for the development and use of cellulosic biofuels. In conducting its research, Sandia utilized models that examined current and future technologies for development of ethanol.

Future enhancements to Sandia’s BDM are planned, contingent on additional partnerships. Such improvements to the current software tool, says Sandia business development associate Carrie Burchard, would provide an even more comprehensive systems understanding of the biofuels industry.

Producing 45 billion gallons per year cellulosic ethanol by 2030 requires 480 million tons of biomass, of which 215 million tons comes from dedicated energy crops. Allowing for storage, loss, and immature perennial crops, these energy crops utilize 48 million acres of planted cropland from what is now idle, pasture, or non-grazed forest. The simulations assume technological progress in the conversion technologies, which results in average biomass conversion yields of over 95 gallons of ethanol per dry ton of biomass by 2030.

Ethanol ‘seed-to-station’ floor cost is approximately $1.50/gal-ethanol without taxes, and gasoline will undercut this if priced below $2.25/gal-gasoline without taxes (about $2.65 at the pump).

Transportation CO2 savings were 250 million tons CO2 equivalent per year for 60 billion gallons of ethanol (excluding greenhouse gas emissions from land use change – a current topic of intense research). The energy in cellulosic ethanol is about 3.8 times the energy content of fossil fuels used for the entire supply chain (production and distribution; numbers based, in part, on assumptions in GREET). This is about 4 times the net energy ratio for gasoline (0.8).

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.