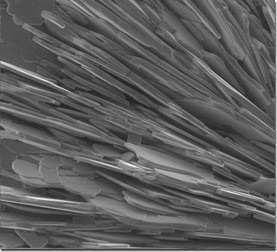

Sample of BSCCO-2212. Section pictured measures about 120 microns wide.

$4 million in DOE funds will enable the Magnet Lab to investigate the complex copper oxide superconductor with the unwieldy name of bismuth strontium calcium copper oxide, or BSCCO-2212. They are seeing if BSCCO will enable a new generation of more powerful superconducting magnets. (32+ Tesla for BSCCO instead of 24 Tesla max for Nobium magnets) Superconducting magnets are 40 times cheaper to operate than permanent magnets at high field (20+ Tesla) strength.

BSCCO material is unique among all of the so-called high temperature superconductors because it can be made into round wires, a product form that is much more flexible for making magnets. The goal of the new Magnet Lab research is to thoroughly understand BSCCO-2212’s performance limits and to construct superconducting research magnets far more powerful than those currently made with niobium-based materials.

“This material is very promising, but it’s very complex and not very strong,” said David C. Larbalestier, the Magnet Lab’s chief materials scientist and director of the Applied Superconductivity Center. “DOE has entrusted us with the funds to make a broad U.S. collaboration that directly addresses both the fundamental processing and grain boundary science of these fascinating materials and their application to new generations of magnets, both at the Magnet Lab and in the DOE high-energy-physics laboratories.”

Traditional, niobium-based superconducting materials cannot generate magnetic fields above about 24 tesla, but in October of 2008, Mag Lab engineers constructed a BSCCO-2212 test coil that achieved 32 tesla. (Tesla is the scientific unit of measure of magnetic field strength; 32 tesla is more than 3,000 times stronger than a refrigerator magnet.)

At the Mag Lab, the average cost to run a resistive magnet is $774 per hour – 40 times more than a 20-tesla superconducting magnet, because once a superconducting magnet is brought to full field, it can operate perpetually. That would allow scientists to remain at high fields for hours and even days, since operating costs would be dramatically lower than they are now.

Niobium superconducting magnets at wikipedia

Niobium becomes a superconductor when lowered to cryogenic temperatures. At atmospheric pressure, it has the highest critical temperature of the elemental superconductors: 9.2 K. In 1992 alone, niobium-titanium wires were used to construct more than 1 billion US dollars worth of clinical magnetic resonance imaging systems.

BSCCO-2212 (Bi2Sr2Ca1Cu2O8) has a critical temperature of 95 K.

This is a higher temperature than Niobium and would allow for liquid nitrogen cooling which is cheaper. The boiling point of liquid nitrogen is 77 K. BSCCO is a Type II superconductor. The upper critical field in BSCCO polycrystalline samples at 4.2 K has been measured as 200±25 TBi2212 was the first high-temperature superconductor to be used for making superconducting wires. Although it has the same problems with weak links at crystal grain boundaries as YBCO, for BSCCO this can be overcome by a texture evolution during the rolling process due to Van-der-Waals coupled BiO layers, which are not present in YBCO. However, its critical current density (maximal Amps per square Metre of cross-sectional area) in magnetic fields at elevated temperatures is ~480 A/cm2, about a factor 10 less than that of YBCO. Both Bi2212 and Bi2223 can be made into wires via the Powder-in-tube process

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.