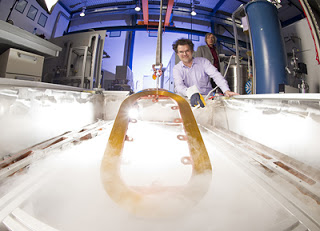

Siemens and the Karlsruhe Institute of Technology (KIT) plan to demonstrate that high-temperature superconductor technology is suitable for power generation in everyday operation. The research project, which was recently launched, aims to improve generator efficiency by 0.5 percentage points to 99.5 percent. Large power plants would achieve significant fuel savings and thus greatly reduce their carbon dioxide emissions as a result of such an increase. The picture shows the prototype of a coil in a container with liquid nitrogen for cooling.

Siemens and the Karlsruhe Institute of Technology (KIT) plan to demonstrate that high-temperature superconductor technology is suitable for power generation in everyday operation. The research project, which was recently launched, aims to improve generator efficiency by 0.5 percentage points to 99.5 percent. Large power plants would achieve significant fuel savings and thus greatly reduce their carbon dioxide emissions as a result of such an increase. The project will be presented at the SuperConducting City during the Hanover Fair (April 4 to 8, 2011).

The experts from Corporate Technology — the central research organization at Siemens — have acquired a great deal of experience with regard to electric motors and generators whose coils are made from high-temperature superconductors. These superconductors have an operating temperature of around minus 240 degrees Celsius. The electric current density possible with such windings is approximately 30 to 100 times greater than the values achievable with copper coils at room temperature. Following tests on a 400-kilowatt model motor, a four-megawatt (MW) generator operating at 3,600 rpm was subjected to a program of long-term tests. This was followed by tests on a 4 MW high-torque motor at 120 rpm. Each of these projects showed that the high-temperature superconductor technology halved the machines’ losses while also reducing their size and weight.

The plan is now to make this efficiency advantage available to power plant generators. The increase in efficiency from 99 to 99.5 is also noteworthy at powers of 150 to 900 MW. Achieving this goal is complex. The mechanically sensitive HTS cables in the generator rotor must resist a centrifugal acceleration of 5,000 times that due to the earth’s gravitation. At the same time, it must be possible to reliably cool them to minus 240 degrees.

A rotation test stand is to be set up at KIT under real-world operating conditions — after all, generators in power plants have to be extremely reliable. The project will study cryostat concepts, thermal insulation, and cooling processes. A generator of this type also requires robust high-temperature superconductor windings with a high current capacity. The development of a rotating, superconducting test coil represents a milestone in the project, which is scheduled to run until 2014. It is being financed by the German Research Ministry. The long-term objective is the development of a prototype generator that uses high-temperature superconductors and can generate a power of several hundred megawatts.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.