Pinnacle Engines today unveiled plans to commercialize a breakthrough ultra-efficient engine by 2013. The new engine design enables significant reductions in fuel consumption and greenhouse gas emissions without increasing vehicle cost. Pinnacle also announced it has raised $13.5 million in venture funding from NEA, Bessemer Venture Partners and Infield Capital.

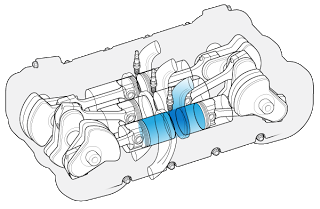

Pinnacle Engines’ ultra-efficient engine is based on a four-stroke, spark-ignited (SI), opposed-piston, sleeve-valve architecture. It achieves 30 – 50% better fuel economy in various drive cycle comparisons without the large cost penalty normally associated with dramatic fuel economy improvement. The performance of the Pinnacle Engines design has been independently verified by FEV, Inc., a globally recognized leader in engine development and a Pinnacle Engines development partner.

“Engines that can deliver significant efficiencies within 5 – 10 years are critical as the global demand for vehicles places a strain on both natural resources and the environment,” said Rohini Chakravarthy, Pinnacle Board member and a Partner at NEA. “We believe Pinnacle Engines is in a unique position to have a major impact in that timeframe, by delivering exceptional efficiency gains at the lowest possible cost.”

The core of Pinnacle’s technology resides in its unique engine architecture and its Cleeves Cycle. The Cleeves Cycle operates on the Otto cycle (constant volume combustion) or Diesel cycle (constant pressure combustion) depending on operating conditions. Additional efficiency improvements will be realized through incorporation of variable valve timing, direct injection, turbocharging, and Pinnacle’s own low-cost variable compression ratio mechanism. The result is a fundamentally more fuel efficient and scalable engine design, and one that is compatible with most fuels including gasoline, diesel, natural gas, propane and their biofuel replacements (e.g., ethanol).

The patented Pinnacle Engines architecture and the innovative Cleeves Cycle are the culmination of over 100 years of combustion engine design, and forty years of research and innovation by founder and CTO Monty Cleeves – a long-time innovator in multiple fields, and a dedicated student of engine design. “This engine technology provides the fuel economy and CO2 emissions of a hybrid at a price that the whole world can afford,” says Cleeves.

The company is in the process of commercializing its technology through a joint development and licensing agreement with an Asian vehicle OEM. Production is slated to commence in Q1 2013. Further developments, including plans for expansion into the global automotive market, will be revealed later this year.

“By 2016, more than 200 million combustion engines will be manufactured globally. Pinnacle technology could make them considerably more efficient while dramatically reducing the costs required to achieve those efficiencies,” states Ron Hoge, Pinnacle’s new Chairman and CEO. “Monty Cleeves’ lifelong dream to design a much more efficient internal combustion engine is becoming a reality. The opportunity to be a part of this exciting new engine company with its game-changing technology and capability to scale quickly and affordably was something I couldn’t pass up.”

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.