Business analysts may poke fun at the “impossibly” expensive cost of mining nearby celestial bodies such as asteroids, or even the moon, but these pursuits are not beyond the realm of possibility.

Returning to the moon for the purposes of mining will require new technologies and new ways of thinking, and this extends to the conventional business model. We cannot write these pursuits off based on high cost alone, especially given the hidden treasures to be found.

I believe that after many years of experimental work in small laboratories I have come up with a mining technology that fits the lunar condition: suction extraction with pneumatic transportation.

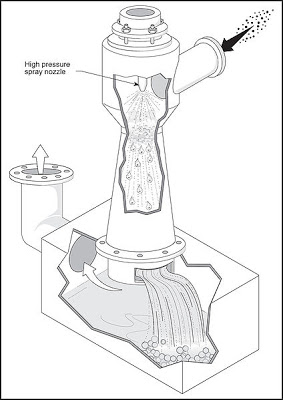

This technology uses airflow, much like water, to transport material that is small enough it can be sucked by a Venturi process, into a pipe and transported from a high-pressure entry to a low pressure exit point.

I need to add a caveat here in that I have not tested this technology (yet) in the lunar environment. Still, it requires a minimal mass to be launched to the moon as it relies heavily on in-situ resource utilisation (ISRU).

So, rather than transporting pipes for moving minerals, my concept would use the readily available silicates and the solar heat energy available on the moon to manufacture and join glass pipes on site.

This is one cost-saving mechanism: relying on materials that are already available. It’s similar to how the First Fleet relied on fresh water, trees and stones to build houses, barracks and bridges in what would become Sydney.

A second critical feature of our mining process is that it’s a dust-free operation. Gene Cernan, a lunar astronaut on Apollo 17, highlighted my apprehension about creating dust when he said: “I think dust is probably one of our greatest inhibitors to a nominal operation on the moon.”

A pollution control device can be adapted to lunar mining the regolith

Wikipedia – Ejector venturi scrubber

Finally, extracting and transporting the lunar soil to the processing plant is highly efficient as it utilises the lower lunar gravity as well as its dry and powdery characteristic as a resource. In this way, we would minimise the energy required to operate a lunar mine.

There is obviously much work still to be done, and many naysayers to convince, but it’s not a pipe-dream without proponents.

Some investors forecast lunar mining will start by 2016. Mining on asteroids, some analysts believe, will have to wait in line until 2022.

Time will tell how these plans will be realised but there is no question that mining on the moon and asteroids will eventually happen.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.