A Cambridge University study suggests that offshore wind farms could be 100 per cent more efficient in terms of energy payback if manufacturers embraced new methods for making the structures that support the turbines.

As wind farms are increasingly sited offshore rather than on land, and installed at water depths of up to 40 metres, a Cambridge University engineer is urging the wind power industry to look again at the design of the heavy supporting towers and foundations used out at sea in order to improve the energy payback achieved.

Jim Platts of the Institute for Manufacturing (IfM) believes that the wind power sector could achieve significantly higher payback ratios if turbine manufacturers used guyed towers (towers held in place by steel cables) made in composite materials rather than free-standing towers made in conventional steel materials.

A preliminary study undertaken at IfM suggests that payback ratios for offshore wind farms could be doubled if the industry embraced new construction methods.

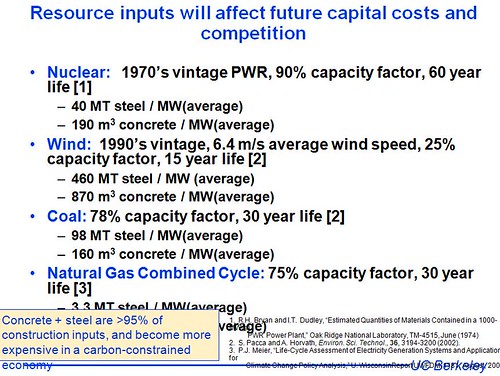

Wind turbines use about 10 times more steel and 5 times more concrete to generate the same amount of power as a nuclear power plant. One thousand 3 megawatt wind turbines are needed to equal one 1 GW nuclear power plant. The wind turbines have about 30% capacity factor. Those wind turbines would be 60 stories tall. Apparently the offshore wind turbines use 2.5 to 3 times more steel and concrete for the same power and are more inefficient in terms of material needed than onshore wind.

Per Peterson, Prof at Berkeley provides information on construction material for energy. 95% of construction inputs are steel and concrete.

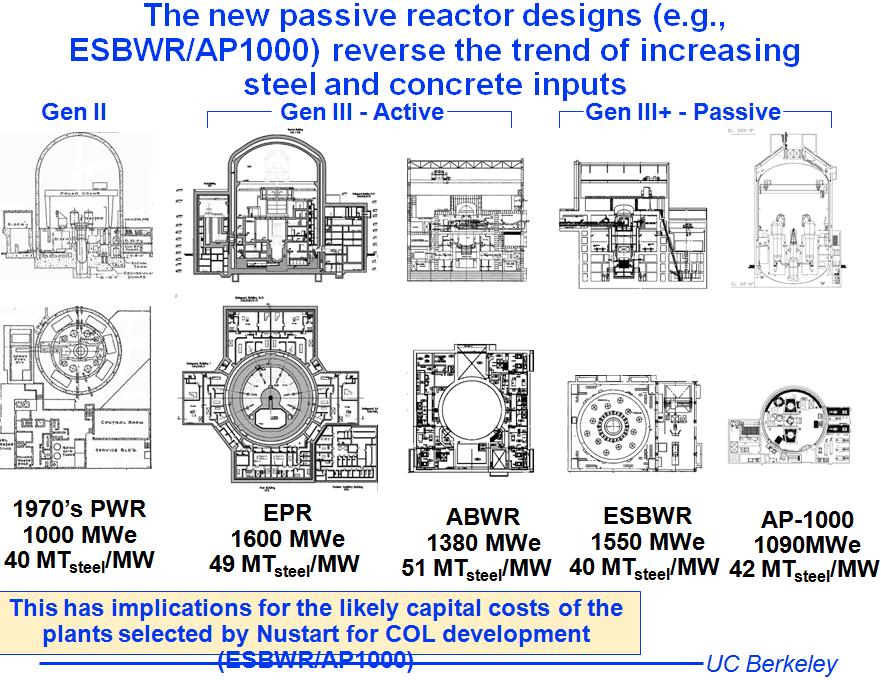

China is making 1250MW AP1000’s now, 1400MW in the next batch and 1700MW for the ones after that

Wind turbines comprise three main elements: the blades that harness the wind energy; the gearbox and generator mechanisms that produce the electricity; the tower that supports these moving parts and the foundations that hold the tower in place. The tower is conventionally made of steel and the foundation in steel and concrete.

For a turbine designed for use on land, the energy embedded in the moving parts represents two-thirds of the total energy invested in the installation while the supporting structure (tower and foundation) represents the remaining third. Onshore turbines typically achieve a harvesting ratio of 40:1.

When wind turbines are sited offshore, the towers required are both taller and heavier and the foundations more massive, using up to four times the amount of steel and concrete. “When you look at offshore wind turbines you see a series of slim structures – what you don’t see are the far heavier supporting structures below the surface that they slot into,” said Platts.

Both steel and concrete are highly energy intensive to produce so the harvesting ratio of offshore turbines reduces to typically 15:1 – far lower than for onshore turbines.

On top of this, offshore turbines are subject to corrosion, which reduces the lifespan of the steel used. “Steel is prone to corrosion and to fatigue,” Platts explained. “This begs the question: could we do better with other materials. The answer is yes, we can use composites for towers just as we do for blades. They are lighter, stronger, corrosion free and more resilient than steel.”

A preliminary study undertaken by the Institute for Manufacturing suggests that guyed towers offer significant advantages over conventional towers. The use of steel cables, fixed to the sea bed by screw anchors, means that towers can be significantly slimmer as the tent-like guyed shape distributes the loads more efficiently to the seabed. Similarly, the foundations required are substantially less weighty.

The resulting reduction in the volume of steel and concrete needed means that a harvesting ratio of 25:1 can be achieved, the study concluded.

“The use of guyed towers is just the first step for the industry to take. The second step would be to make towers in composite materials which are less energy intensive to make than steel which relies on smelting and concrete that also depends on a chemical reduction process in manufacturing cement. Composites also have a longer life than steel as they stand up to fatigue much better. Using these new materials could increase the harvesting ratio still further to 32:1 and extend the lifetime of a turbine installation from the present 20 years to up to 60 years,” said Platts.

Manufacturers of turbines have driven advances in composites, producing materials with 95 per cent of the performance of the high-cost composites made for the aeronautical sector at 5 per cent of the cost.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.