SolarCity installs 25% of the residential solar panels in the United States.

SolarCity said it was in talks to build a giant solar-panel factory near Buffalo, New York “At a targeted capacity greater than 1 Gigawatt within the next two years, it will be one of the single largest solar panel production plants in the world,” the company said in a blog post.

If the solar industry were to generate 40 percent of the world’s electricity with photovoltaics by 2040, that would mean installing more than 400 GW of solar capacity per year for the next 25 years. We absolutely believe that solar power can and will become the world’s predominant source of energy within our lifetimes, but there are obviously a lot of panels that have to be manufactured and installed in order for that to happen.

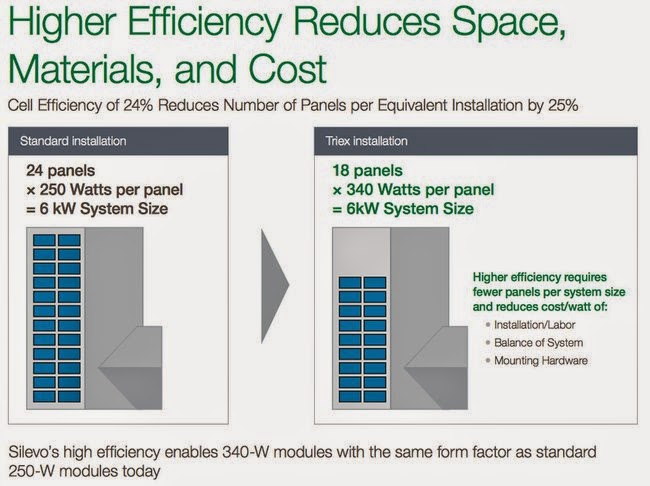

SolarCity is acquiring Silevo for as much as $350 million in an all-stock deal. Silevo is known for its high-efficiency Triex modules, and SolarCity CEO Peter Rive said in a conference call that the company was eventually aiming to produce panels with 24 percent efficiency.

Tesla plans to build a battery “gigafactory” that by 2020 will have the capacity to produce just over 10 times the amount of batteries used in all electric vehicles in 2013.

Tesla wants to be in production by 2017 — three years from now — and at max capacity as soon as 2020. The “giga” in the name apparently comes from the 2020 plant capacity: 35 gigawatt-hours (GWh) per year in cells, 50 GWh/year in packs, suggesting Tesla would bring in batteries from outside.

The Gigafactory will facility have 10 million square feet.

Combined having the largest solar panel and advanced battery factories means that Elon Musk can provide cheaper solar power with battery storage

Installing solar panels on your roof is still one of the most expensive ways to generate electricity — costing roughly twice as much per kilowatt-hour as building a new natural-gas plant, on average. (Federal subsidies [30% of the cost] bring the price of solar down, but those tax credits are at risk of expiring.)

SolarCity made its name by pioneering the field of solar financing, which allows people to pay a monthly lease to get solar power without having to acquire the actual hardware. A critical piece to making leases economic is the 30 percent federal investment tax credit, but that will shrink to 10 percent in 2017. That leaves SolarCity and the rest of the solar industry looking for ways to lower the cost of delivering energy from solar, both for leased and purchased systems. And without a sufficient supply of panels, SolarCity won’t be able to maintain its rapid growth.

By acquiring efficient cell technology and buildings its own factory, SolarCity hopes to expand solar’s reach and further disrupt the electric utilty industry status quo. “Being fully vertically integrated allows us to control the cost of solar per kilowatt-hour installed, which ultimately is the metric that matters,” said CEO Lyndon Rive.

If you liked this article, please give it a quick review on ycombinator or StumbleUpon. Thanks

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.