1.

A proposal to construct two 600 MWe high-temperature gas-cooled reactors (HTRs) at Ruijin city in China’s Jiangxi province has passed a preliminary feasibility review, China Nuclear Engineering Corporation (CNEC) recently announced.

The Jiangxi provincial development and reform commission has already given the go-ahead to begin preliminary work at Ruijin and construction of the reactors is expected to start in 2017, with grid connection in 2021

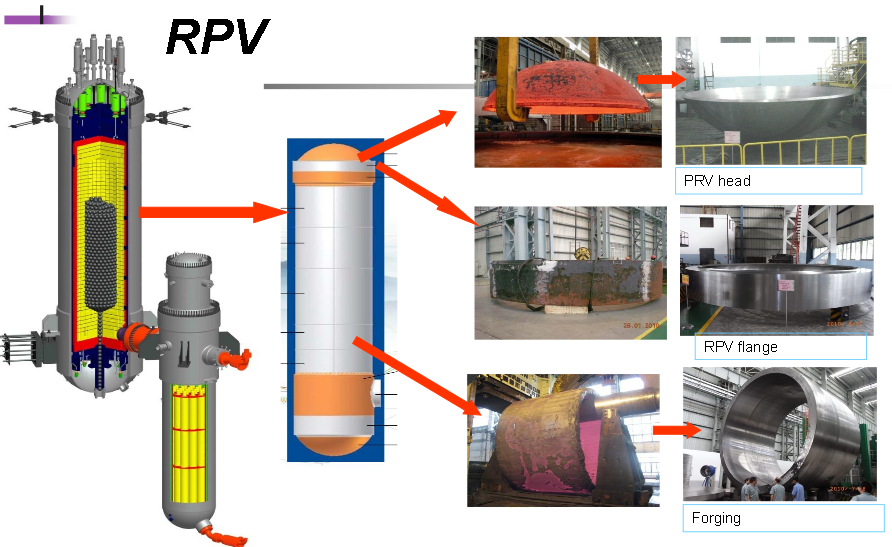

The design of the Ruijin HTRs is based on the smaller demonstration HTR-PM under construction at Shidaowan near Weihai city in Shandong province. That plant will initially comprise twin HTR-PM reactor modules driving a single 210 MWe steam turbine. Construction started in late 2012. CNEC said civil construction work on the HTR-PM is nearing completion and equipment installation would soon begin. The demonstration unit is scheduled to start commercial operation in late 2017.

Pebble bed reactors should be walk away safe.

UPDATE – Correcting the reason for the passive safety for this reactor design.

Safety because of smaller modules that cannot reach temperature exceeding Pebble fuel

There are conceptual designs for 4, 6, 8 and even 10 reactor modules all connected to a single steam turbine. The designers are sticking with smaller power output reactors. Calculations tell them that if they keep total output power less than 300 MWth they can make a testable claim of inherent safety. No conceivable event can lead to a situation where the temperature in any part of the core exceeds the 1600 C design temperature for the TRISO particle fuel.

2. Construction of China’s first two CAP1400 reactors at Shidaowan in Shandong province awaits final approval. However, site preparations for the units are well advanced with the pouring of concrete for the foundations of the first unit’s conventional island having now begun.

Work on the turbine building’s foundation is under way (Image: SNPTC)

The CAP1400 is an enlarged version of the AP1000 pressurized water reactor developed from the Westinghouse original by SNPTC with consulting input from the Toshiba-owned company. As one of China’s 16 strategic projects under its National Science and Technology Development Plan, the CAP1400 is intended to be deployed in large numbers across the country. The reactor design may also be exported.

Huaneng Group’s Shidaowan site is part of a larger Rongcheng Nuclear Power Industrial Park, at which two prototype 105 MWe HTR-PM small modular reactors are already under construction.

SOURCE- World Nuclear News

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.