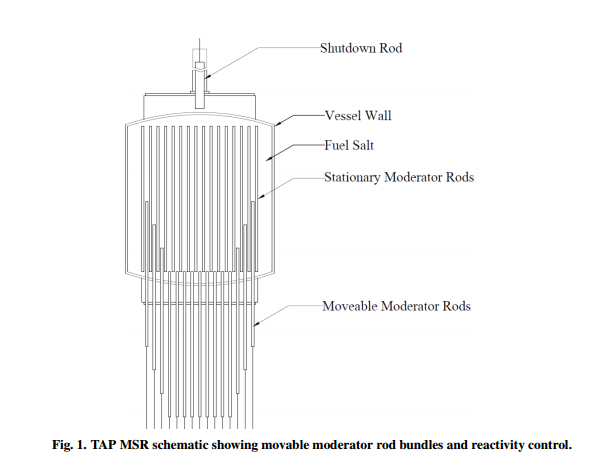

Presenting the results from the first phase of the collaboration between Transatomic Power Corporation (TAP) and Oak Ridge National Laboratory (ORNL) to provide neutronic and fuel cycle analysis of the TAP core design through the Department of Energy Gateway for Accelerated Innovation in Nuclear, Nuclear Energy Voucher program. The TAP design is a molten salt reactor using movable moderator rods to shift the neutron spectrum in the core from mostly epithermal at beginning of life to thermal at end of life. Additional developments in the ChemTriton modeling and simulation tool provide the critical moderator-to-fuel ratio searches and time-dependent parameters necessary to simulate the continuously changing physics in this complex system. Results from simulations with these tools show agreement with TAP-calculated performance metrics for core lifetime, discharge burnup, and salt volume fraction, verifying the viability of reducing actinide waste production with this design. Additional analyses of time step sizes, mass feed rates and enrichments, and isotopic removals provide additional information to make informed design decisions. This work further demonstrates capabilities of ORNL modeling and simulation tools for analysis of molten salt reactor designs and strongly positions this effort for the upcoming three-dimensional core analysis

A recent Third Way report detailing $1.3 billion in private investment in advanced reactor technology includes several liquid-fueled molten salt reactor (MSR) concepts. Interest in these MSR concepts is driven by the enhanced safety, economic, and promising fuel cycle benefits of these advanced reactor concepts. The Department of Energy (DOE) Office of Nuclear Energy established the Gateway for Accelerated Innovation in Nuclear (GAIN) to provide private companies pursuing innovative nuclear energy technologies with access to the technical support necessary to move toward commercialization.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.