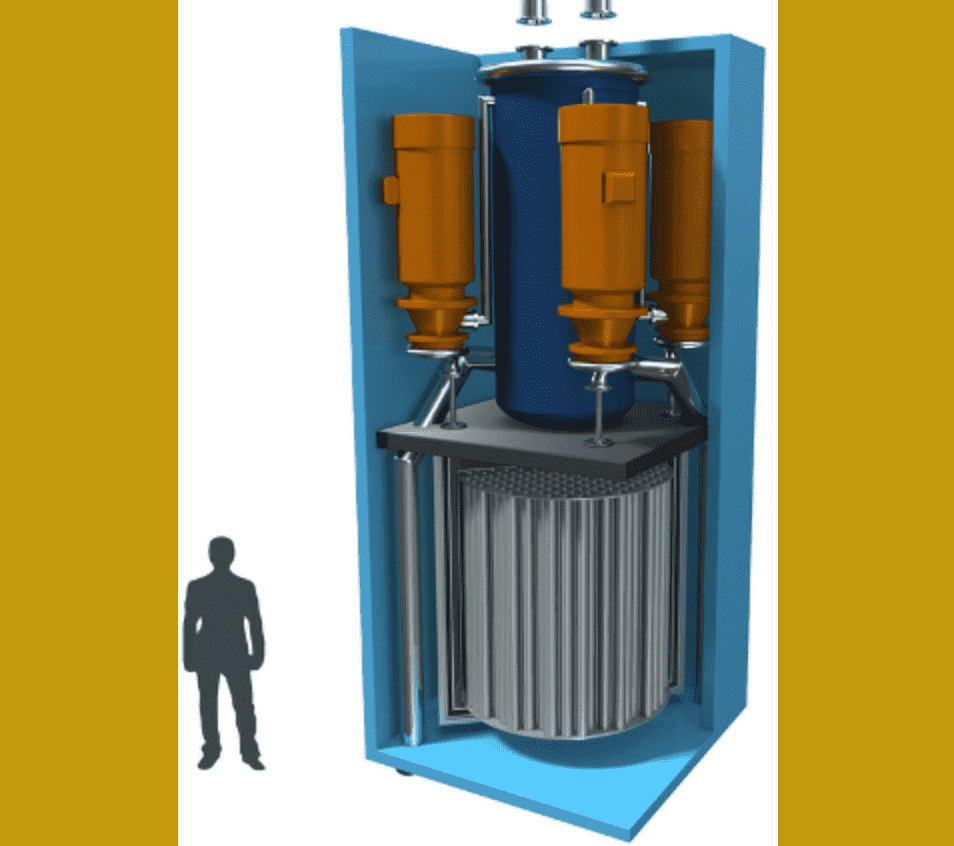

Seaborg is the largest reactor design start-up in Europe. They have a design for a molten salt reactor that is ten times smaller than the Terrestrial Energy IMSR. It would 20 to 30 times smaller than an existing pressure water nuclear reactor for submarines.

Seaborg CUBE reactor can use spent nuclear fuel (SNF) by adding thorium as a catalyst. The CUBE as a waste burner. Current conventional reactors use about 4% of the uranium fuel rods. This is because they use Uranium 235 and cannot use the Uranium 238.

250 MW Thermal for 100 MW of electricity,

The fits it a half-length 20 foot shipping container

35 ton MSR Game changer in SMR-MSR size:

cuboid of 2.4 meters by 2.4 meters x 6 meters, and 30 tons Development

Timeline aligned with standard IAEA reactor development method

• 2014-2016: Pre-conceptual Design Phase 1

• 2017-2018: Pre-conceptual Design Phase 2; 1.5 Million Euros

• 2019-2020: Conceptual Design Phase; 10 Million Euros

• 2021-2024 Technical Design Phase; 50 Million Euros

• Ready to build reactor blueprints

Delivered cost for 250 MW thermal MSR in 2025 in the $50 Million to $70 Million depending upon manufacturing scale. They are working towards a 50 MW thermal pilot plant and then would scale to 250 MW thermal for a commercial system.

Factory Serial Production

Seaborg’s solution is to innovate on cost in several dimensions:

• Safety-by-physics

• Simpler, compact design

• Serial production

• Low grid integration costs

• Low running costs

The CMSR reactor can provide industrial heat and heat for desalination of water

This versatility equates to an immense, global potential.

• Base-load electricity production

• Load following in electrical grids with variable

renewable energy

• Combined electricity and district heating

• Combined electricity and desalination

• Stand-alone, reliable electricity for remote are- as and mining operations

• High temperature heat for industrial processes, including hydrogen, ammonia and synthetic fuel production

CMSR as waste burner

The CUBE is a waste-burner it will still leave some radioactive bi-products behind. The amount of remaining waste is vastly reduced and what is left has a half-life much shorter than what was put into it. The half-life is reduced from several hundreds of thousands of years down to 20-30 years. This makes the handling of the waste much more practical, affordable, and environmentally-friendly than for conventional reactors, since no long-term storage is needed.

Safety of CMSR

The CMSR is a simple device. Whereas convention-al nuclear reactors depend on complex engineered safety systems, the CMSR relies on the laws of physics.

The ingenuity is the molten salt. By combining the fuel and coolant in a liquid salt medium, a host of benefits is derived, including:

• No pressurized water in the reactor

• Operation at atmospheric pressures

• Self-regulating temperature

This results in a transformative approach to nuclear safety by implementing safety-by-physics rather than safety-by-engineering.

The CMSR design is much simpler, and the reactor is walk-away safe.

• Retention of radioactive material within the salt

• Freeze plugs that drain the core to passively-cooled tanks in case

Reprocessing today

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

Very interesting potential development. No wonder that after a century and a half, the Standard Oil Rockefellers announced they were dropping fossil fuels from their portfolio of owned and controlled industries.

BUT what I’d really like to know is how the heck they plan to tie into this thing. 100mw output would require a cable so heavy and large, ten men couldn’t drag it into place. It would need mechanized connectivity at specific stations. Or am I missing something?

Seaborg (Element 106 Seaborgium) knew that with the political and military mentality in the USA that World War 3 was an inevitable event without a change to a global “development” system of Cooperation, Collaboration and Concern for Others Between Nations – https://worldinnovationfoundation.blogspot.com/2018/12/seaborg-element-106-seaborgium-knew.html

Did they get through Level 1 testing yet?

Did they get through Level 1 testing yet?

Also, the concrete is not the pressure vessel” – No it’s a steel forging so large and heavy that only 1 or 2 companies are tooled up to make it. “BWR is indeed tight fitting compared to a PWR containment” Go look at a modern BWR you can actually get permission to build today like ABWR or ESBWR. It’s not that tight fitting. On ABWR it looks by eye that the radius of the containment is 4 times the radius of the pressure vessel and a little less than twice the height. ESBWR looks to be about 5-6 times the radius of the pressure vessel and a little less than twice the height. That’s 30-70 times the volume of the pressure vessel. On a PWR volume of the containment is what, 500 times the volume of the pressure vessel? It’s absolutely bigger, but both are enormous and made of nuclear grade concrete and steel forged, welded and tested to very high standards.

Also” the concrete is not the pressure vessel”” – No it’s a steel forging so large and heavy that only 1 or 2 companies are tooled up to make it.””””BWR is indeed tight fitting compared to a PWR containment””””Go look at a modern BWR you can actually get permission to build today like ABWR or ESBWR. It’s not that tight fitting. On ABWR it looks by eye that the radius of the containment is 4 times the radius of the pressure vessel and a little less than twice the height. ESBWR looks to be about 5-6 times the radius of the pressure vessel and a little less than twice the height. That’s 30-70 times the volume of the pressure vessel.On a PWR volume of the containment is what”” 500 times the volume of the pressure vessel? It’s absolutely bigger but both are enormous and made of nuclear grade concrete and steel forged”” welded and tested to very high standards.”””

I know these containments very well and there is a lot of concrete involved, but the containment of a BWR is indeed tight fitting compared to a PWR containment. Also, the concrete is not the pressure vessel; pressure vessel is a rather thin vessel made to withstand about 40 psig; the concrete supports the thin metal wall. The containment dome “head” is only about twice the 15′ diameter of the reactor vessel (i.e. about 25′ across). PWR containments are huge because they are meant to pressurize to 40 psig during a large-break without sparging steam into a suppression pool. Some PWR have a smaller containment like DC Cook because they actually keep borated ice in the containment. BWR construction costs are significantly lower than PWRs, still they are both on the same order of magnitude and nobody wants to build them anyways.

I know these containments very well and there is a lot of concrete involved but the containment of a BWR is indeed tight fitting compared to a PWR containment. Also the concrete is not the pressure vessel; pressure vessel is a rather thin vessel made to withstand about 40 psig; the concrete supports the thin metal wall. The containment dome head”” is only about twice the 15′ diameter of the reactor vessel (i.e. about 25′ across). PWR containments are huge because they are meant to pressurize to 40 psig during a large-break without sparging steam into a suppression pool. Some PWR have a smaller containment like DC Cook because they actually keep borated ice in the containment. BWR construction costs are significantly lower than PWRs”””” still they are both on the same order of magnitude and nobody wants to build them anyways.”””

Did they get through Level 1 testing yet?

” Also, the concrete is not the pressure vessel” – No it’s a steel forging so large and heavy that only 1 or 2 companies are tooled up to make it.

“BWR is indeed tight fitting compared to a PWR containment”

Go look at a modern BWR you can actually get permission to build today like ABWR or ESBWR. It’s not that tight fitting. On ABWR it looks by eye that the radius of the containment is 4 times the radius of the pressure vessel and a little less than twice the height. ESBWR looks to be about 5-6 times the radius of the pressure vessel and a little less than twice the height. That’s 30-70 times the volume of the pressure vessel.

On a PWR volume of the containment is what, 500 times the volume of the pressure vessel? It’s absolutely bigger, but both are enormous and made of nuclear grade concrete and steel forged, welded and tested to very high standards.

I know these containments very well and there is a lot of concrete involved, but the containment of a BWR is indeed tight fitting compared to a PWR containment. Also, the concrete is not the pressure vessel; pressure vessel is a rather thin vessel made to withstand about 40 psig; the concrete supports the thin metal wall. The containment dome “head” is only about twice the 15′ diameter of the reactor vessel (i.e. about 25′ across). PWR containments are huge because they are meant to pressurize to 40 psig during a large-break without sparging steam into a suppression pool. Some PWR have a smaller containment like DC Cook because they actually keep borated ice in the containment. BWR construction costs are significantly lower than PWRs, still they are both on the same order of magnitude and nobody wants to build them anyways.

It is a front for grad school projects in Denmark. It’s not real. It’s Denmark for chrissake.

While his initial comment, “I think size is important” is amusing enough – in a “that’s what she said” context, the remark that “The reactor design needs to be of a size that allows a startup to complete the regulatory requirements…” makes no sense. Of all the regulatory requirements, size is not one. The regulator doesn’t care if it is small or large as long as it isn’t a near zero power experimental facility (university reactor). You can spend all the time and money you want to validate a 300MW reactor; it will likely be similar to the time and money spent to validate a 5000MW reactor.

Not to mention, it is just a bogus front for grad school projects in Denmark – the most greentarded country in Europe.

Gah, it filtered my links. Well I guess you can find them yourself.

You’re wrong. It’s not tight fitting and it’s 1-1,5 meters of reinforced nuclear grade concrete with rebar the size of your arm. Look at e.g. ESBWR or ABWR, not a BWR mark 1.

http://www.hitachi-hgne-uk-abwr.co.uk/reactor.html

https://nuclear.gepower.com/content/dam/gepower-nuclear/global/en_US/documents/product-fact-sheets/ESBWR%20Passive%20Safety%20Fact%20Sheet.pdf

Even if you for some reason must look at a mark 1, the steel bottle is on a massive concrete pedestal and is encased in meter-thick concrete: see e.g. https://jdwaggoner.files.wordpress.com/2011/03/bwr_schematic.jpeg

Super keen to see this kind of tech reach fruition. Would like to know more about the companies behind these ideas – how solvent are they, are they public or private companies, who are the people behind them, what are the timelines for R&D and production … etc.

Never heard of the movie either.

I guess this answers why I didn’t make any plutonium nyborg jokes.

It’s a reference from the movie Heavy Metal, as a substitute for cocaine…

Never heard of her? Is it a video game character?

I believe that Drew’s comment means: If the reactor is nice and small, then it would be made in large numbers. If it is made in large numbers then (the argument goes) a number of good things happen:

1. You can set up a production line (remember, they are small enough to truck/plane/ship out to the installation site). We know that making things on production lines makes them much cheaper.

2. Because it is a standard product made on a production line, standard production engineering approaches will refine the design and iron out any quality issues.

3. Because it is a standard product made on a production line, regulatory approval can be given for the design, so you don’t need individual regulatory inspections and approvals for each power plant, so you get huge savings in time and money.

4. Because it is small and easy to transport and easy to get approval for, it can be used in more locations, leading to a bigger market, return to step 1.

I don’t know enough about the whole thing to say if this argument is valid, but it seems to work with other sorts of machinery.

Huh?

I think the size is important. The reactor design needs to be of a size that allows a startup to complete the regulatory requirements and still allow them to build multiple units to prove the design and have a large enough market to create the possibility for profit. The design appears to lend itself to common applications like water desalination and also create distributed power creation. Hope they succeed.

Still only going to kill a few stupid grave robbers. The fuel is cooled by natural convection in a sealed, slightly pressurized can – air cooling will do just fine if they pop it open in 100 years. If it deteriorates in the O2 atmosphere there is no reason to suspect environmental dispersion worse than Oklo. Oklo was a stream and dispersion was quite minimal (stuff stayed put).

Now, what should be put on the cask is an engraved plate with the best-estimate of isotopic inventory. That would be useful in the future instead of trying to sort out documentation from the 21st century.

BWR containment is a tight-fitting, steel bottle with a pool in the bottom. It is not as you say. Facts are cool!

All this and no plutonium nyborg jokes?

If the Egyptian pharohs had access to cool glow-in-the-dark grave goods that were guaranteed to throw a real deadly curse on grave robbers they would have gladly used all they could.

It’s still a containment vessel, still fairly large and made of meter-thick concrete with rebar the thickness of your arm. MSRs are atmospheric pressure.

BWRs have always had quite a small containment compared to PWRs – were you aware?

“Seaborg CUBE reactor can use spent nuclear fuel (SNF) by adding thorium as a catalyst.” — Thorium is not a “catalyst”. It may be a fertile source of fissile U233, if there are enough spare neutrons around to sustain both fission and breeding. No mention of how CUBE will do that.

“CUBE as a waste burner” — Nothing “burns”. SNF is ~95% not “waste” but valuable U238 for Pu breeding, or just making new LWR fuel, or M1 tank rounds.

“Current conventional reactors use about 4% of the uranium fuel rods. This is because they use Uranium 235 and cannot use the Uranium 238.” — Trumpian! The law requires dilution of U235 below bomb materiel, so 5% U235 & 95% U238 is typical new LWR fuel.

Calling the company Seaborg is an exploitive marketing ploy. Shame.

—

Dr. A. Cannara

650 400 3071

BS. Who cares. Darwin award.

“Current conventional reactors use about 4% of the uranium fuel rods. This is because they use Uranium 235 and cannot use the Uranium 238.”

That’s not really correct just like the nightly news butchers the message. Plenty of 238U gets used in reactors that contain it. The stuff fast fissions and that is up to 7% of the neutron balance, and it absorbs epithermal neutrons giving plutonium that is burned in situ. Just so happens that fuel cladding wears out at 5% atom burnup, so there is that too. You’d have to re can it.

Passive safety is much easier in smaller reactors. The show stopped in LWRs is that the containment building has pretty large economies of scale because it is always too large to massmanufacture. If you can make a reactor the size of a gas turbine and not require a pressure vessel; you can get economies of scale by making more units instead of larger reactors.

I don’t care about how small it is. I want cheap electricity and heating. Make it a 5 floor tool 5GWe reactor for all I care. Hell, I’m quite sure bigger is better for economics until some rather large size. Give me that.

This sort of reactor would be better used in container or bulk cargo ships. Plenty of room and even Goat’s weight calculations wouldn’t be a show stopper.

Even more than the (hopefully) profits from this system, the issue of waste elimination is crucial. I believe int was Seaborg himself who coined the term of “a Faustian bargain regarding nuclear waste. To rob tombs is apparently human. They are doing it in Central America today. Indiana Jones is a folk hero. The Egyptian pharoahs caught one of their work gangs tunneling in at night to rob tombs. Ten thousand years from now, there will likely be tomb robbers with no inkling of what they are carting back to the hide out … and sprinkling a trail of death behind themselves. No, consider the waste fission byproducts as a resource stream and “burn” those materials in profitable advanced fission reactors.

you got your plus one for humor.

LOL, channeling Yoda you try.

Lest anyone forget … maybe the BRAND NEW, as-yet-unfueld, as-yet-not-irradiated¹ CORE might fit in a 1-TEU can, as per the fake blueprint marketing visual, but the “thing” sitting in its operating bowl will not be anywhere near so portable.

Have to have a stoutly built, leakproof, seismically durable, well-immune-to-radiation non-pressure vessel “bowl” in which to house the incredibly radioactive core once it starts up for production. Remember… its a SOLID rectangular cube-shape (rhomboid?) … with a specific gravity in excess of 7 metric tons per m³.

The specific density of both uranium and thorium chlorides/fluorides is pretty high. 5.5 to 6.5 mt/m³ … and if it WERE “1 TEU” in volume, that’d be 270 tons.

270 tons Without pipes, pumps, moderator insertion motors, instrumentation, failsafe sluices and whatever else must need be installed to get the thing operational (and yes, ignoring supercritical CO₂ gas turbines, their heat exchangers, exhaust waste-heat mechanisms and all that).

Just saying.

1 TEU is pretty optimistic.

GoatGuy

_______

¹ once irradiated by nuclear fusion high energy neutrons, all the metals (atoms) of the core are slowly but also irreversibly transmuted to other isotopes, some of which are variously themselves spontaneously radioactive. You can “turn off” a nuclear fission core easily enough. But it won’t be “walk-up-safe” for … decades to centuries … And certainly not “shippable in a TEU” to a disposal location. Right?

Vital part of NRC certification- the “regular truck 35 mph 7% grade slope challenge”

Begun the regular truck sized reactor wars have.