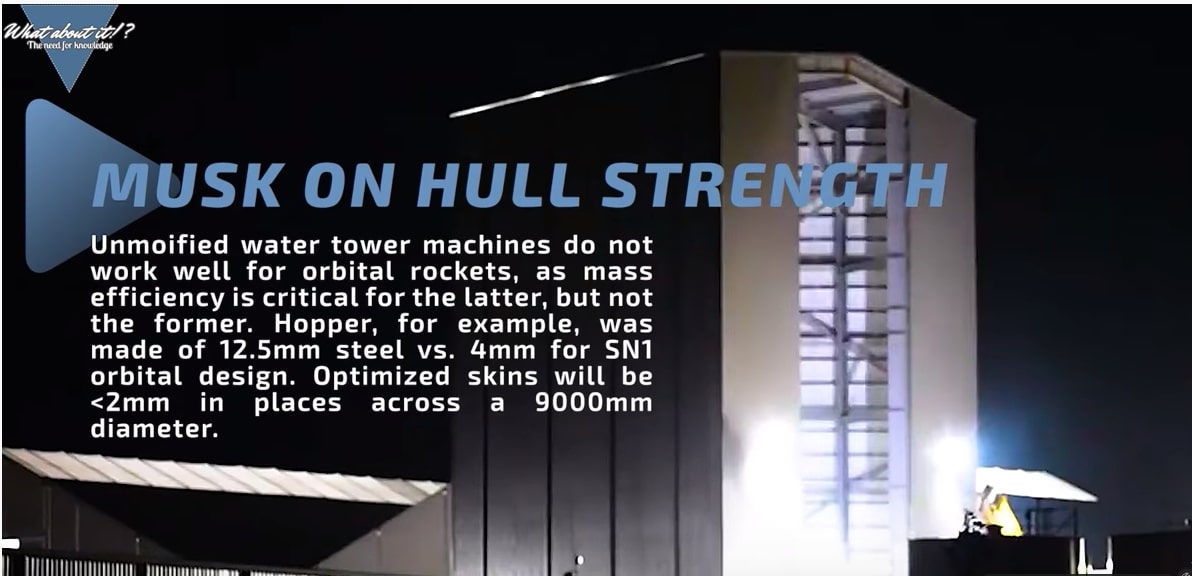

Felix Schlang did some calculations of the weight of the ring segments with the Serial number one starship which is using 4 millimeter thick steel. These segments weigh 1622 kilograms. They are less than one-third of the thickness of steel used for the Starshopper. The optimized Starship will have some sections where steel is half as thick at 2 millimeters. These would weigh 810 kilograms.

There are about 15 of the 1.82 meter tall rings on a SpaceX starship. This would mean the outer hull steel would weigh about 15-20 tons.

The Super Heavy booster is taller than the Starship. It would weigh about 20-25 tons for the outer hull. There may need to be some heat shield in some spots and there is all of the internal full tanks, bulk heads and other material.

There is a rendering picture below by Kimi Talvitie and another from @Fael097.

Videos by Felix Schlang at What About It

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

The last two landings didn’t go totally right. What they are doing is very hard. The fact that they are mostly successful still amazes me.

It won’t matter how short the hop is if the they don’t stick the landing. It is just a metal tube. If it don’t land square it will crumble on one side and fall over. I think it will take a few tries to get it right.

Look if money was no object, create tungsten alloy CMF construction, that would be optimal in all regards. Technically if you could manufacturer, it would provide aluminum density with titanium alloy level strength.

I think the biggest question is, when will they build the first booster?

They’ve got a fair amount of experience with those landings now. There’s even the potential that they could have the control software autotune on the way down.

There are going to be a lot of short hops first so maybe that will lessen the probability of catastrophic failures???

Perhaps the strangeness is the speed of development and then conversion to mass production. I guess ICBMs had/have to be made at scale. However there’s something about the way SpaceX attacks the engineering and manufacturing problems with such relentlessness and ultimate success that seems very different from anything in the past.

“A total of 13 Saturn V rockets were launched from 1967 until 1973″.

Two things I think we may see in the coming months. Due to the lack of accuracy in the ring bending machines, SpaceX will end up creating their own. Once such a machine is made then look forward to ring segments doubling in width. I am betting that they are looking for any way they can to reduce the number of welds.

Always amazed and encouraging of new and different ways of doing things. Good luck Starship.

Was thinking about the Starship SN1. I think it will be about 90% probability it will launch and 90% probability that the landing won’t go well.

I think it will take about five attempts to stick the landing. What they are trying to do is hard.

Be prepare for a few heart breaks but don’t give up since the successes will be spectacular.

He’s just a German you-tuber and space enthusiast.

BB answers with mastery… Goat bows…

I’d expect the booster to stay shiny, (I don’t think it ever gets hot enough to change color.) and the Starship to become colorful.

Stainless steel is “stainless” because the chrome content forms an adherent chrome oxide layer which blocks further corrosion. And which is self-healing, any scratches just grow their own layer. It’s also transparent.

Expose the steel to heat in an oxidizing atmosphere for an extended time, and oxygen gradually penetrates that layer, causing it to grow thicker. Eventually it gets thick enough to create colors from light interference, like you see in a soap bubble.

It’s got nothing to do with changes in the micro-structure, it’s not the steel’s color, it’s the oxide thickness.

Not quite the same thing as the color changes you see in feritic steels during heat treat, which are actually the iron changing between oxidation states as a result of reaching different temperatures, which makes the color changes useful in assessing your heat treat status.

Here’s a little more information: https://www.bssa.org.uk/topics.php?article=140

troo… but it also won’t likely come back ‘silver’ either.

https://cdn.thefabricator.com/a/all-you-need-to-know-about-the-heat-affected-zone-2.jpg

GG

I would just start with the total area, not each strip.

Even at that size it would be like taking a pop up camper to mars…

I once heard a biologist say that biology was not rocket science, it was far more complex. Did not seem to recognize that rockets do not already exist.

From the coil spec I get a density of 7900 kg/m^3 (= m/L*w*t). Then that times 0.205 m^3 is 1620 kg. Not a big difference either way, but closer still.

As for titanium, it’s much more difficult (and expensive) to work with, and the material is more expensive too.

hopefully it will have pretty annealing colours

https://upload.wikimedia.org/wikipedia/commons/thumb/a/aa/Tempering_colors_in_steel.jpg/800px-Tempering_colors_in_steel.jpg

This Félix guy is amazing… I was wondering if he was on the staff of spacex…

Floating in a long tin can….

faaaar above the moon…

can you hear me major Tom…

That’s equal strength titanium at what temperature? Musk’s point was that at very high and cryo temps SpaceX stainless was very similar or better to the best alternatives.

On that we will agree for sure. Nice and shiny. Wonder what it is going to look like after it gets back. Millennium Falcon, anyone? GG

“It hasn’t been rocket science”, for quite awhile, actually.

The basic physics (and engineering) of rocketry hasn’t changed one iota¹ in the last 25 years. 95%, unchanged in the last 50 years³. Before that, was the nascent² period of rapid and exciting rocket science research and development. And spectacular failures. Jaw dropping.

⋅-⋅-⋅ Just saying, ⋅-⋅-⋅

⋅-=≡ GoatGuy ✓ ≡=-⋅

________________________________________

¹ – iota is the little ‘dotless’ “i” in the Greek alphabet. It, being the smallest letter, is whimsically then a reference to any vanishingly small thing. Not one iota! Hah!

² – nascent means ‘just being born’ or close to that. So, fresh, brand new tech is considered ‘nascent’. Poppin’ outa’ the egg, baby!

³ – OK, Musk’s Big Fûqueing Rocket has a brand new engine powered off methane (cow fâhrts) and oxygen. That’s new. However, its specific thrust isn’t new. Kind of between delicious hydrogen-oxygen (Shuttle) and much easier to handle kerosene and oxygen. (Apollo Moon shots)

ring = 1.82 m ‘wide’

circumference = π diameter

… = 28.27 m

strip area = ‘wide’ • ‘long’

… = 51.46 m²

strip volume = area • thickness (= ⁴⁄₁₀₀₀ m)

… = 0.205 m³ per strip.

Steel density = 8,050 kg/m³

… = 1,656 kg/ring. Close enough!

That’s a lot of mass. For an equal strength bunch of titanium sheet, at 4,506 kg/m³, the same would weigh in at almost exactly 1,000 k.

The difference, multiplied by the 15 rings is just under 10,000 kg. TEN tons of payload. No wonder just about every ‘other’ program uses titanium where they can. As in everywhere.

But stainless definitely has the corner on the ‘not likely to catch on fire in the passing hypersonic atmosphere.’ Titanium tends — once it is afire — to burn like a Fourth of July white-hot flash firework.

Anyway, just showing that like most things, it doesn’t take a PhD to multiply areas and thicknesses to get volumes, and Google stainless density, to get mass. H. S. math, actually.

⋅-⋅-⋅ Just saying, ⋅-⋅-⋅

⋅-=≡ GoatGuy ✓ ≡=-⋅

Strange, coming the Apollo era, to see so much available thrust and so much (now) “conventional” engineering and construction being applied. Is it no longer “rocket science”?

Stainless steel first stage looks pretty awesome!

Good to see high quality and high production rates. It looks like they have made some serious progress over Mark 1. Maybe we will see a launch in March, after all. If not April?