Florida researchers propose a new method, called Aqua Factorem, to extract lunar water. It will drastically reduce energy and complexity of lunar mining operations helping to establish this industry. Other methods to extract water from the regolith are based on phase change, pumping energy into the regolith to sublimate the ice into vapor, then capturing the vapor, re-freezing it, and hauling the solid ice to a chemical processor where it is converted again into vapor for purification then electrolysis. This requires transporting high power into the permanently shadowed regions (PSRs) not only to vaporize the ice in situ in the soil but to heat the surrounding soil itself, which is wasted energy. Still other methods are based on strip mining and hauling the resource along with slag (the unwanted silicates, which constitutes about 95% of the mass), to a processing unit that is located outside the PSRs. That may be a simpler architecture but is generally not favored because hauling 49,000 t of regolith over many kilometers yearly to produce the projected demand of 2,450 t of propellant would be terribly difficult and expensive with high risk that the vehicles will get stuck driving with such loads across the unprepared regolith.

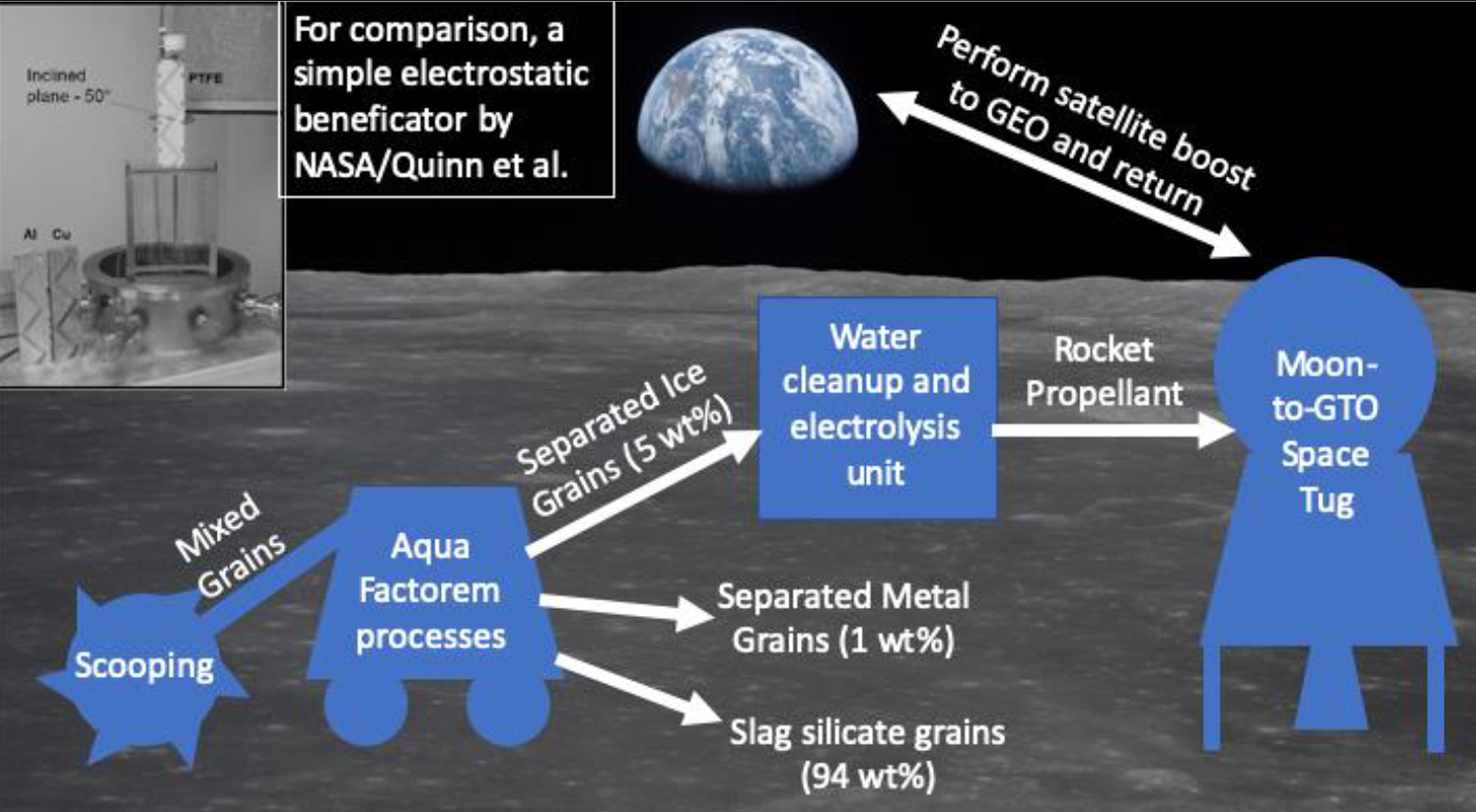

The new approach takes advantage of the processing that the unique lunar geology has already performed. Micrometeoroid bombardment has already broken most solid material in the upper part of the regolith into fine grains. This includes solid material of all compositions, including the ice, which is as hard as granite at PSR temperatures and is therefore essentially another type of rock. These ice grains are intermixed with all the other minerals, so a simple, ultra-low-energy grain-sorting process can extract the ice without phase change. As another benefit it can extract the 1 wt% free metal known to be in lunar soil, again with very little energy. The ice can then be hauled to the chemical processing unit in solid phase and converted into rocket propellant.

They estimate the 800 kW power needed for thermal extraction can be reduced to less than 100 watts using the new method. This affects the entire architecture of the mining operation producing extensive economic benefit, which we will quantify in this study. They will look at a mission to mine propellants commercially for space tugs that boost commercial communication satellites from Geosynchronous Transfer Orbit (GTO) to Geostationary Orbit (GEO) then return to the lunar surface for refueling. This simple architecture requires the minimum number of in-space elements, and notably does not require an in-space propellant depot, so it provides the lowest cost and lowest risk startup for a commercial operation. The study will also test the innovative Aqua Factorem process through laboratory experiments, and this will produce basic insights into the handling of lunar resources.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

Thanks. If I’m reading that right, it looks like vacuum welding is a relatively trivial effect, and the regolith is mostly just a pile of rubble, with larger chunks being held together by glass.

I wonder if that might be different for the polar region, since water ice is supposedly deposited more or less an atom at a time and continuously.

So even though the surface is created by continuous meteorite impact, causing fragmentation and ejection, with the ejecta redeposited as rubble, nonetheless that surface might subsequently be welded back together by water molecule deposition?

It’d be a continuous race between micrometeor fragmentation and water ice welding. Maybe that’d give lots of layers of thin sheets of ice-bound material separated by loose dusty aggregate, but then mostly broken up by micrometeor impacts.

Also, water ice having a lower melting point than the rock, it might more commonly bind ejecta together, making for larger agglutenate rocks.

They only cement together where they touch. At the very top you’ve got what they call a “fairy castle” structure, that’s practically fractal, and very low density. As you go down it gets denser, presumably reaching full density at some point. Here’s a good reference:

https://www.lpi.usra.edu/publications/books/lunar_sourcebook/pdf/Chapter09.pdf

Is there any link to details of this beyond the NASA proposal above? What ARE these “Aqua Factorem” processes?

In a way, the Aqua F machine is similar to the initial experimental O’Neill *plant* that would get O, glass and metal slag from equatorial stuff, with lots of heat. I think this was to justify collecting the material rather than to be done at scale, but ?. At any rate, the main big question is to rockets or mass driver eventually, as you say. Here a factor of refueling rockets to leave Moon is thrown in, as you say, certainly important at first w/o mass driver. Another consideration is the cost of the AF moving *all* the stuff but then dumping most of it back down, v the cost of dragging it up to the start of the mass driver and into Space. Perhaps also compare the cost of the AF on the Moon and in Space. Another thing is that the O can be trivially heated out in Space, so you get almost all of the fuel weight easily, it not being from the water. Launch H and C from the Moon, perhaps. A very interesting set of possibilities!

So does this technique rely on the regolith being in the form of sand and dust?

Doesn’t the regolith vacuum cement grains together, below the top few centimeters?

Does it break up really easily?

That depends upon what the stages are. My first stage would be experimenting in Space, rather than trying to do things on the Moon. It seems to be hard to visualize not having all that stuff to move things, over and over, while not dropping it. Most of the Moon plant would not exist in Space. Just one high energy but simple push, and 0 g from there on, unless g is desired. Little reason to have humans on the Moon, or any planet, for that matter. It is not “the right place”.

These projects are still using rockets to launch material into orbit from the moon.

Hence, you need to extract your rocket fuel on the surface of the moon. Taking the ice, plus 20x the mass in dross, to orbit isn’t possible.

If and when they get solar powered mass drivers, slingshots etc. installed on the moon, then you can send it all up. But that is at least a couple of stages in the project after the one that this is aimed at.

Looks like 94% of the overall, the slag, still has to be moved, just not mass driven or carried to orbit. If something can be found to do with this other material in space, where the energy is not so tight, it can all be cooperatively orbited and this Aqua Factorium can be done there, in Space, where it will be far easier, esp at larger scale. Why do people just assume without notice or justification that a planet is the place to do these things?