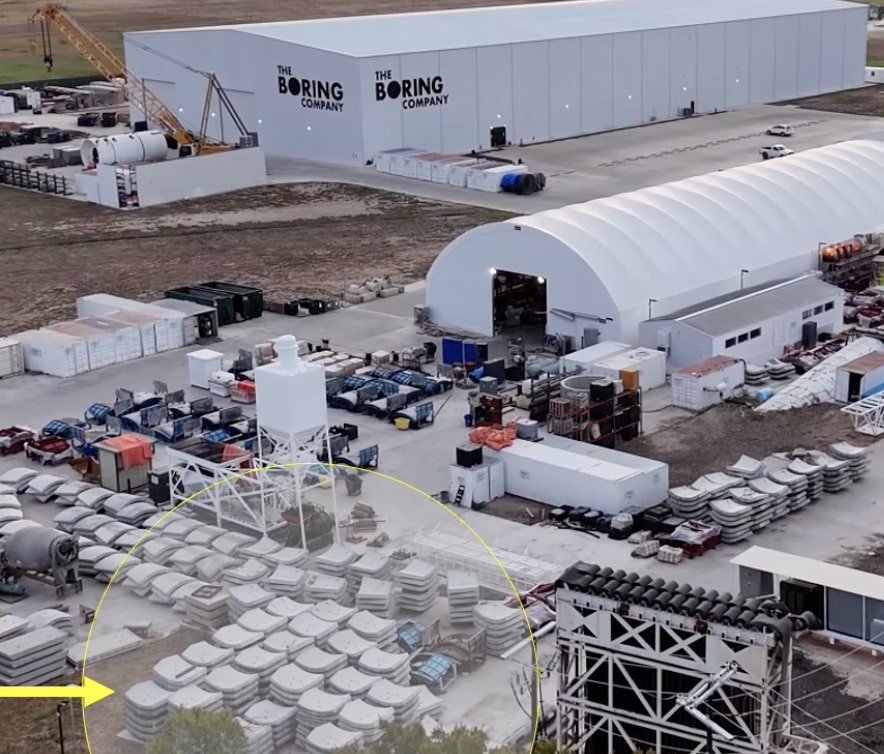

The Boring Company (TBC) has been building tunnels at about 40 meters per day. This is for the digging and for the concrete reinforcement of the tunnel. Will at the Boring Revolution Youtube channel has spotted hundreds of hexagonal concrete segments at the Boring Company. This means that Boring Company has changed its tunnel walls to hexagonal pieces. This will enable one type of wall segment and tunnel construction with tunneling and wall construction of over 100 meters per day.

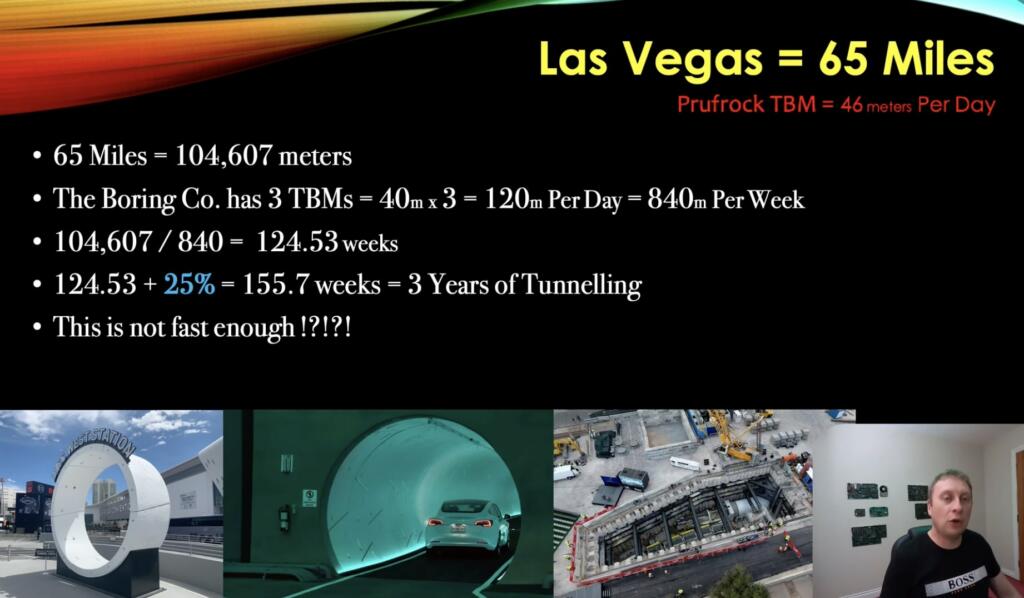

This could nearly triple the construction speed. Will had been calculating that TBC Prufrock III machines would be able to build tunnels at 40 meters per day or 280 meters per week. Six machines would build 1680 meters per week. It would take 1.5 years to complete the 104,000 meters (64 miles) of the Vegas Strip construction project. Six machines each building 100 meters per day, 600 meters per week would enable 4200 meters per week. This would enable the completion of the Vegas tunnel and tunnel construction in about 6 months.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

I would see huge opportunities in hydroelectric tunneling from lower lakes as reservoirs to high reservoirs. In addition, certain segments of other pipelines through difficult terrain might be more profitable than transporting people in cars.

Imagine for instance, a tunnel from the Atlantic to the Pacific at a 12 ft differential near Panama. The high volume tunnel even at low head would produce massive electricity!

If they’re all the same, it won’t be possible to form bends or correct direction. What is their plan for this?

Will indicated in his advantages and disadvantages list that there needs to be some 120 meter curve length for the hexagonal wall method. So it can form bends and direction changes.

Are the segments reinforced, or just concrete? What type of concrete? There are many types with differing properties. Is there a moisture barrier? A lot of questions left unanswered here.

Increased tunneling speed is good to see and might accelerate completion on long tunnels, but it will do almost nothing to speed up the Las Vegas loop construction. The glacial pace of permitting and construction of the stations is still causing the whole project to move at a snail’s pace.

Insufficient opportunities for graft. Never assume inexpensive public transport is the goal.

Sorry, trapezoids, maybe not parallelograms!

Conventional TBM tunnels aren’t lined with concrete rings, rather concrete segments that assemble into rings (how are whole rings supposed to be brought through the tunnel?). The segments are parallelograms, with each ring segment oriented so the diagonal parallelogram sides don’t line up. Really hope Boring Company gets to building tunnels that fit trains and actual evacuation+ventilation paths

I would love it more if larger diameter tunnels like railroad tunnels could be built faster and cheaper. NYC needs more tunnels to cross the Hudson and East Rivers. And NYC needs more subway and commuter rail lines. A 50% decrease in cost would save tens of billions and make the projects more likely to be done.

unfortunately many of these transportation projects are just as much about graft and jobs for unions as anything else. Delivering a functional transport system is way down on that list