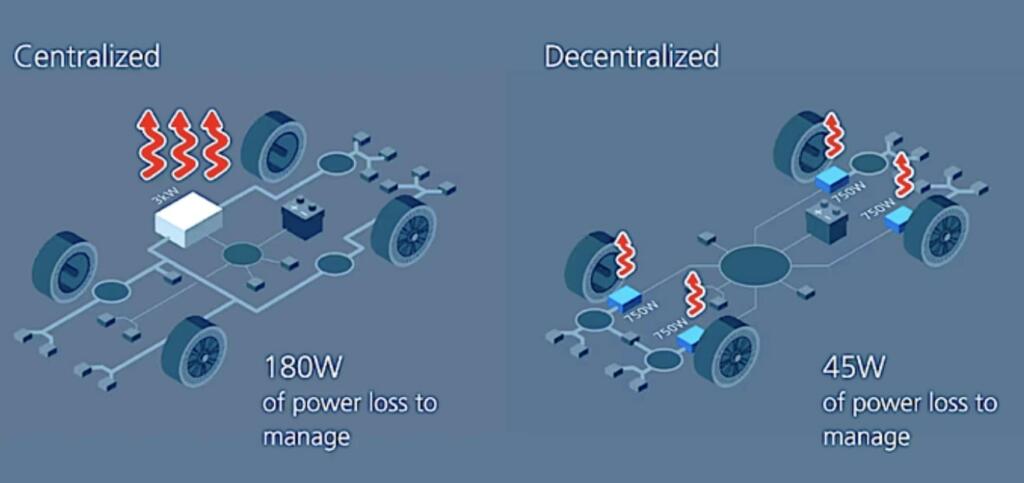

The Tesla Cybertruck is the first car with a 48 volt lower power system and this will save about 70% of the copper used in the vehicle. The Cybertruck is running gigabit ethernet cabling for data along with the 48-volt power on the same cable. This uses 4 times lower amperage and replaces the device to device CAN bus.

It will be interesting to see when Tesla will be able to convert the Model Y, Model 3 and the Semi over to the ethernet and 48-volt power system. Tesla has given the rest of the auto industry a guide to converting to 48-volts. Tesla has to convert all of its own products over to 48-volt. It seems likely that the Model Y refresh at the end of 2024 would include a 48-volt refresh. The Model 3 and Model Y share a lot of parts so both could transition at the same time. This could be limited by suppliers and the supply chain for the new 48-volt components ramping up production volume.

Instead of running one wiring harness to the driver door speaker, and another to the driver’s door window motor, they can daisy-chain them together on the same self-contained cable interface. Your computer could connect to your door handle using the same wire that’s already been through your speaker, window, ambient lights, and steering wheel. Each of those devices/components listen to the continuous stream of data for a command relevant to its operation.

Tesla has its own secret accessories team dedicated to developing products specifically for the 48-volt architecture, such as lighting, winches, and air compressors. These products are designed to work seamlessly with the CyberTruck systems, offering customers a wide range of high-quality accessories that are tailored to the vehicle’s capabilities. Tesla will make better products and create new revenue streams.

The simplified wiring of a daisy chained system between components also reduces the number of chips used in the car. This is hugely important because of the shortage and restricted supply of automotive chips. The shortage of chips is being relieved but eliminating the need for up to half the chips is still cost savings. The work on wiring harnesses is labor intensive. Simplifying the wiring reduces the overall labor in the car and speeds up the work getting the built car through the factory.

Floppy wires are more difficult for Teslabot to handle. Human factory workers and Teslabots would have an easier and faster time with rigid components that can be snapped into place. Tesla redesigning and simplifying the wiring gave Tesla the opportunity to have a wiring product and processes that are more Teslabot friendly.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

Have to correct you here: The world’s first 48 volt car is not a Tesla. It’s the nanoflowcell Quantino, which just turned 25 years old. For proof, see the 35 second mark of the video here: https://www.nanoflowcell.com/research-development/application-research/mobility/quantino-twentyfive or in this still picture: https://www.nanoflowcell.com/research-development/application-research/mobility/quantino-twentyfive. 48Volt is literally nameplated on the rear fender of the 2,000km range Quantino – still by far the highest range of any electric car.

The batteryless bi-ion powered Quantino is ultimately powered up in minutes from a saltwater dual solution which is completely non-polluting and could be available at every current fueling station with a small amount of retrofitting. https://www.nanoflowcell.com/research-development/application-research/mobility/quantino-twentyfive.

The Quantino arguably outperforms a Tesla in other ways too such as going 0-100km in under 3 seconds, and has been tested continuously for 8 years, over 500,000km.

The 2-seater outlooks the Tesla sportster too, which is now even older than the Quantino, but unlike the Quantino, has not been updated for nearly a decade.

Why isn’t this beast finally out of beta and available for sale?

They write on their super-slick website:

“We are currently in the planning stages for the production of the world first flow cell electric vehicle.

What initially took shape as a research endeavor has seamlessly transitioned into the tangible realm of mass production.

In collaboration with strategic partners, nanoFlowcell is actively scouting the perfect location in New York as we gear up for production.”

I live in NYC. I may never be able to afford this car, but I can’t wait to see them around. Tesla will have some real competition then.

Interesting website. I have a few issues though:

– Outlooking the Tesla roadster is of course a matter of opinion. I prefer the Tesla.

– They are very reluctant to actual say what salts their power carrier has in it. Just “metalic and non-metallic salts” which could be thousands of different things. Though if it really is “not considered hazardous waste” that narrows it down a lot.

-They talk about refilling, with dual hoses, but don’t mention where the old fluid goes. It has to go somewhere. It needs to be recycled I imagine, so the refuelling stations need to have that feature, which isn’t mentioned. Either that or they just dump the “metalic and non-metallic salts” onto the road as you drive along. And even with something as benign as iron salts that would lead to problems very soon.

-And the last problem, and their big disadvantage over BEVs, is that you need a network of these new fueling stations to be established BEFORE you buy a car. At least with an EV you can recharge at home or work long before charging stations become convenient.

One of the advantages of such a high range is that you don’t need a lot of stations to make the car viable though it’s true that no one wants to drive 100 miles to refuel, then 100 miles back again, but at least long road trips would be possible.

Existing gas stations could install the new pumps relatively easily, and they would appreciate a viable business model to ease away from declining oil-based futures.

The dumping of metal salts on the road is a problem, potentially, but they say:

“The truly special features are often and seen. Did you know that seawater, waste water or even industrial waste water can serve as the basis for the bi-ION® electrolyte fuel? Our water treatment plant purifies this into pure, resource-saving process water that we can supplied to the bi-ION® production process. The bi-ION® electrolyte fuel largely consists of water in order to make it pumpable. However, essential element is the suspended nano-structured bi-ION® molecules. These are specifically-designed, performance-optimised charge carriers developed to portably store regenerative energy. This fuel is then used to generate clean electricity in the nanoFlowcell®. Resource-saving, with no harmful emissions, non-toxic, non-flammable, no health risks.”

https://www.nanoflowcell.com/info-center/flow-magazine/one-who-can-do-what-no-other-can-do

It’s hard to tell from that exactly what comes out of the tailpipe other than maybe water vapor, but if it’s too corrosive it’d be a problem for the tailpipe too.

So worlds first viable production car to use 48 volts, darn you obscure products that won’t be around long!

https://en.wikipedia.org/wiki/General_Motors_Hy-wire

It’s kinda like this, a concept car incorporating a lot of good ideas that were floating around. GM said it was putting it in production too but also never did. 48v, drive by wire, etc have been understood to be better for all the reasons Tesla lists for a long time. Nobody could put them in production though.

The best thing is that Tesla’s implementation is basically Ethernet with beefed up PoE (which is typically 48V).

[ ‘https://www.nanoflowcell.com/research-development/application-research/mobility/quantino-48volt’ 2018 data for QUANTiNO (~80kW/200Nm rear wheel motor, lt 5s for 100km/h(?), dry weight ~685kg ), ~85kWh within a 2x72l liquid electrolyte, that’s ~590Wh/l for 13.5-20kWh/100mi or 8.5-12kWh/100km ((guess ~400Wh/kg), ~hydrogen–bromate flow batteries, Tesla battery ~245-290Wh/kg, gasoline ~9.7kWh/l or 12.2kWh/kg)

LCOE (levelized cost of energy) vanadium redox flow batteries (10-20Wh/kg, 15-25Wh/l, energy eff. 75-90%, 1.15–1.55V) target to ~$0.05 (currently ~’few tens of $ cents’)

Hybrid flow cells

‘A prototype zinc–polyiodide flow battery demonstrated an energy density of 167 Wh/l’

Environmental interaction from company marketing

‘The unique benefits of the bi-ION® fuels

Not flammable

Not explosive

Non-toxic

Environmentally friendly

Unlimited shelf life

Refillable

Efficient’ ]

[ for Cybertruck it’s only for the (additional) components (up to ~10-15kW for e.g. huge air condition, starter generators on ICE), for QUANTiNO it’s the drive train motor that’s on 48V (rated 300A from flowCell are constant ~14,4kW)

i see: the twenty-five (2000km range) is different from QUANTiNO called 48VOLT (1000km range), enhancing with 2x125l tank and 4x59kW FWD (torque vectoring), and ~3s for through 100km/h ]

Cybertruck first mass produced 48 volt vehicle. Getting the supply chain companies to support it is the key accomplishment along with the technical implementation.