Researchers from POSTECH and Sogang University developed a functional polymeric binder for stable, high-capacity anode material that could increase the current EV range at least 10-fold over current graphite anode electric car battery range. There is already commercial use of electric cars with 3-8% silicon anode by weight with out 10-30% range increases. There are about 2000 research papers every month on the topic of improvement of silicon for anodes. There is quite bit of lab work with silicon usage in the 30-40% weight range. There needs to be a process with more silicon that can be rapidly productionized and scaled for use in billions of battery cells and millions of electric vehicles.

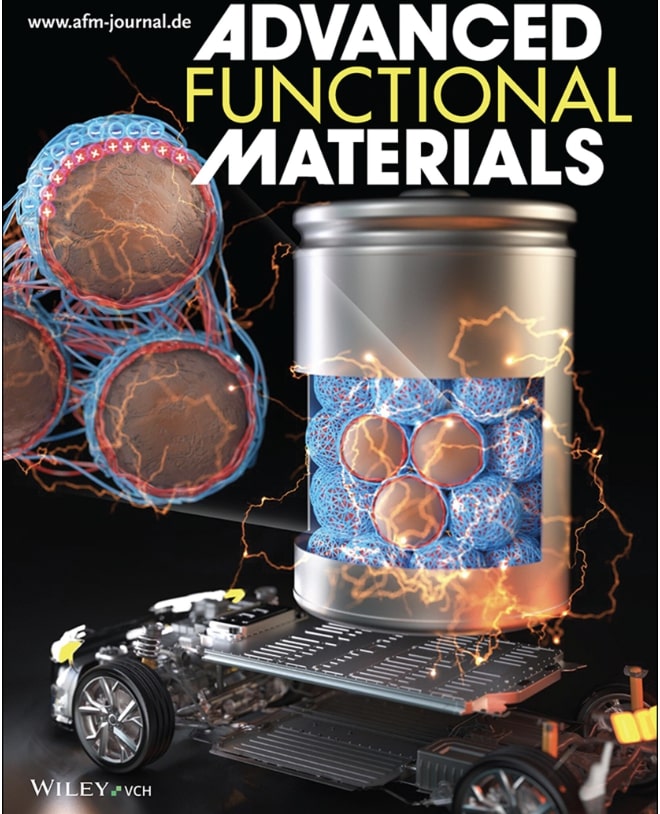

Korean researchers developed charged polymeric binder for a high-capacity anode material that is both stable and reliable, offering a capacity that is 10 times or higher than that of conventional graphite anodes. This breakthrough was achieved by replacing graphite with Si anode combined with layering-charged polymers while maintaining stability and reliability. The research results were published as the Front Cover Article in Advanced Functional Materials.

If there is more silicon in a battery anode then it has more energy. However, silicon expands and can reduce the number of times the anode can be charged and with too much expansion it can break the battery entirely. In 2023, Tesla has reportedly added up to 5 percent silicon in its batteries’ anodes.

Benefits and the Major Challenge of Silicon in Anodes

The reaction mechanism of silicon with lithium is via intermetallic alloying. This reaction allows silicon to provide almost ten times higher capacity (3600 mAh/g) than graphite (372 mAh/g) with the same weight. Using more silicon-based anodes has improved energy density by at least by 30 % of actual values.

Anode manufacturers are introducing silicon into the electrodes but at rather low weight percentages of around 3 to 8 %, due to the complexities presented by silicon during the cycling of the battery: silicon particles undergo enormous volume changes, i.e., up to 300 % of volume expansion (while in the case of graphite it is 13 %).

CIC energiGUNE has published scientific results with high content silicon anodes (30 – 40 weight percentage of silicon at electrode level).

1. 2016, Applied Materials and Interfaces. Silicon-Reduced Graphene Oxide Self-Standing Composites Suitable as Binder-Free Anodes for Lithium-Ion Batteries.

Self-standing silicon-based anodes (silicon-reduced graphene oxide, 40 wt.% of Si) were fabricated and explored, showing great cycling stability (750 mAh/g at 0.05 A/g).

2. Molecules Journal (2020) Towards a High-Power Si@graphite Anode for Lithium Ion Batteries through a Wet Ball Milling Process. A simple, low-cost and easily scalable approach to prepare silicon-graphite composite electrodes (30 wt. % of Si) which exhibited stable capacity values of 850 mAh/g at a rate of 0.25 A/g and outstanding capacity of 770 mAh/g at a rate of 5 A/g, and the importance of the electrode microstructure and design was highlighted.

There are companies like Amprius and OneD trying to use nanowires. Nanowires are a good alternative to conventional flat and round morphologies since volume changes are almost negligible because nanowires leave room for expansion.

Researchers are using CMC for binders that can handle the expansion of more silicon.

There have been about 13000 published articles related to silicon-based anodes in the first half of 2023.

South Korea Polymer Silicon Anode 2023 Research

Research to date has focused solely on chemical crosslinking and hydrogen bonding. Chemical crosslinking involves covalent bonding between binder molecules, making them solid but has a fatal flaw: once broken, the bonds cannot be restored. Hydrogen bonding is a reversible secondary bonding between molecules based on electronegativity differences, but its strength (10-65 kJ/mol) is relatively weak.

The new polymer developed by the research team not only utilizes hydrogen bonding but also takes advantage of Coulombic forces (attraction between positive and negative charges). These forces have a strength of 250 kJ/mol, much higher than that for hydrogen bonding, yet they are reversible, making it easy to control volumetric expansion. The surface of high-capacity anode materials is mostly negatively charged, and the layering-charged polymers are arrayed alternately with positive and negative charges to effectively bind with the anode. Furthermore, the team introduced polyethylene glycol to regulate the physical properties and facilitate Li-ion diffusion, resulting in the thick high-capacity electrode and maximum energy density found in Li-ion batteries.

Abstract

High-capacity anode materials are promising candidates for increasing the energy density of lithium (Li)-ion batteries due to their high theoretical capacities. However, a rapid capacity fading due to the huge volume changes during charge-discharge cycles limits practical applications. Herein, a layering-charged polymeric binder is introduced that can effectively integrate high-capacity anodes using a strong yet reversible Coulomb interaction and enriched hydrogen bonding. The charged polymeric binder builds a dynamically charge-directed network on the active materials with high versatility and efficiently dissipates the electrode stress with its excellent mechanical properties. In addition, poly(ethylene glycol) (PEG) moieties of the charged binder offer a fast Li-ion conduction pathway that can form an ultra-thick silicon oxide (SiOx)-based electrode (≈10.2 mAh cm−2) without compromising the reversible specific capacity and promote effective charge interaction as a mechanical modulator. Such an unprecedented charge-directed binder provides insights into the rational design of a binder for high-capacity anodes.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

I’ve been reading silicon anode articles for at least a decade. I don’t think they’ll ever happen.

Besides, if someone delivers solid state (solid electrolyte) batteries, there won’t be need for anode materials, only metallic lithium. Having nothing there is lighter than silicon.

I’m not sure about the cathode side. Sulfur is often proclaimed there, which also never arrives. It has similar issues with swelling, as well as sulfur not being conductive. Not sure anything can be better than sulfur, short of going to “air” batteries. Something has to be there to attract the lithium ions, I guess.

Eh? BYD cars are sold in those markets.

The only country to give Tesla real competition in The US and Europe is South Korea. (It will be decades before Chinese cars and trucks will be allowed in those markets.

Korean battery manufacturing and research is far ahead of US and Europe. Kia/Hyundai has very cozy relationship with Korean battery manufacturers. Ioniq and EV6 are solid vehicles.

Kia/Hyundai will be much more of a threat to Tesla than GM, Ford, Toyota, Honda, or any European car manufacturer.

Will the nimbleness of Tesla and the federal tax advateges Tesla enjoys be enough to keep the Kia/Hyundai behometh at bay?

Great question…