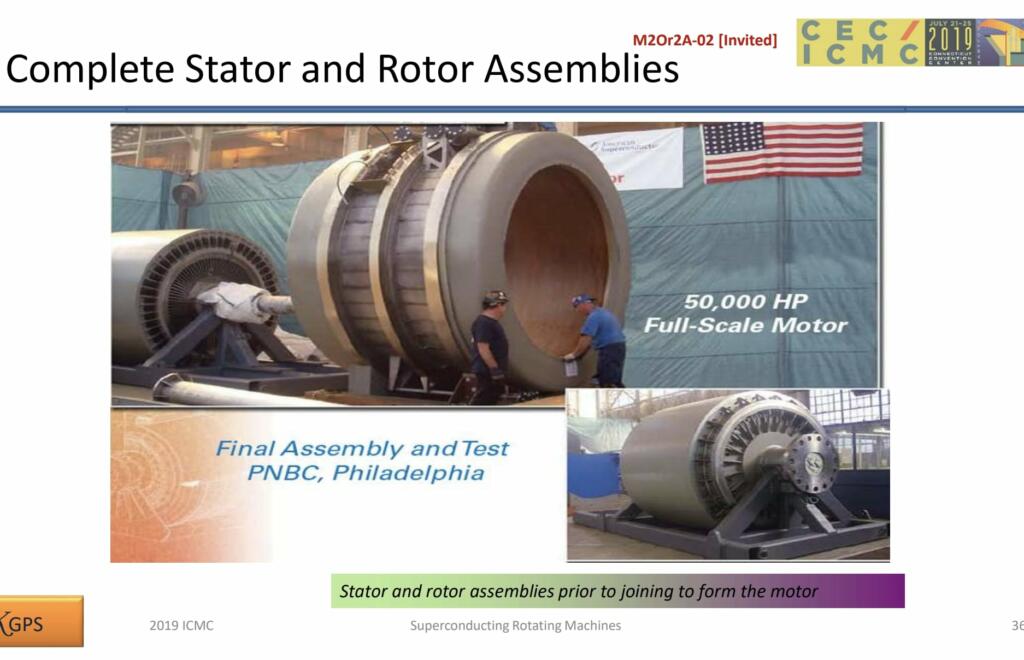

The US Navy has built and tested 5 Megawatt and 36.5 megawatt superconducting engines over ten years ago. All of the tests were good and the specifications were met. They need to lower the cost and increase reliability. Test superconducting motors have been built for large wind power systems. If the LK99 superconductors were real or could lead to room temperature superconductors or even better nitrogen cooled superconductors then the US Navy would be all over it.

The Navy has an overall effort to switch to electric ships. They are working on all kinds of dielectrics and other advanced electrical systems. Going electric will let them separate the general ship power and propulsion platform from the payload and weapons. This is like the skateboard for an electric car that has electric engines and batteries.

The Navy and many others are eager to use superconductors once they can solve the high cost issues. Room temperature superconductors are eagerly awaited because even with liquid nitrogen cooling are still being used for major applications despite the cooling system.

There is an Israeli company working to have a non-electrical outdoor air conditioning system using liquid nitrogen. This would cost about $50-60 to operate each week. Today nitrogen is produced as a byproduct when hospitals and medical services make pure oxygen.

Technology Demo of 5 MW and 36.5 MW Superconducting Engines – they Work waiting to Solve Costs

The Navy is Working on High Temperature Superconducting Components

The US Navy has ongoing high temperature superconductors research directed at applications to support power delivery, pulsed current delivery, alternating current (AC) and direct current (DC) magnetic fields, and magnetic energy storage.

Superconducting materials exhibit lossless DC current transport properties that have potential to enable a wide range of high power density applications including motors, generators, and power cables. Progress towards room temperature superconductivity is being pursued through advances in material science to further reduce size, weight, and cost of conductors used in electrical equipment. Characteristics of superconductors also permit unique capabilities

and unprecedented efficiency in producing and trapping magnetic fields, storing magnetic energy, and integrating inherent fault current limiting capability in conductors and cable topologies.

Cost and Reliability Must Be Improved

• HTS technology amply demonstrated – need for economic viability: – Low-cost HTS wire and – Reliable and affordable cooling system

• MUST: Improve wire performance (e.g., extended window of operation in terms of higher temperature and magnetic field and lower cost)

• Building HTS machines by leveraging synergies of off-the-shelf-components• Designing machines by including dynamic variation of operating parameters (e.g., temperature, excitation, amount of fuel and environment)

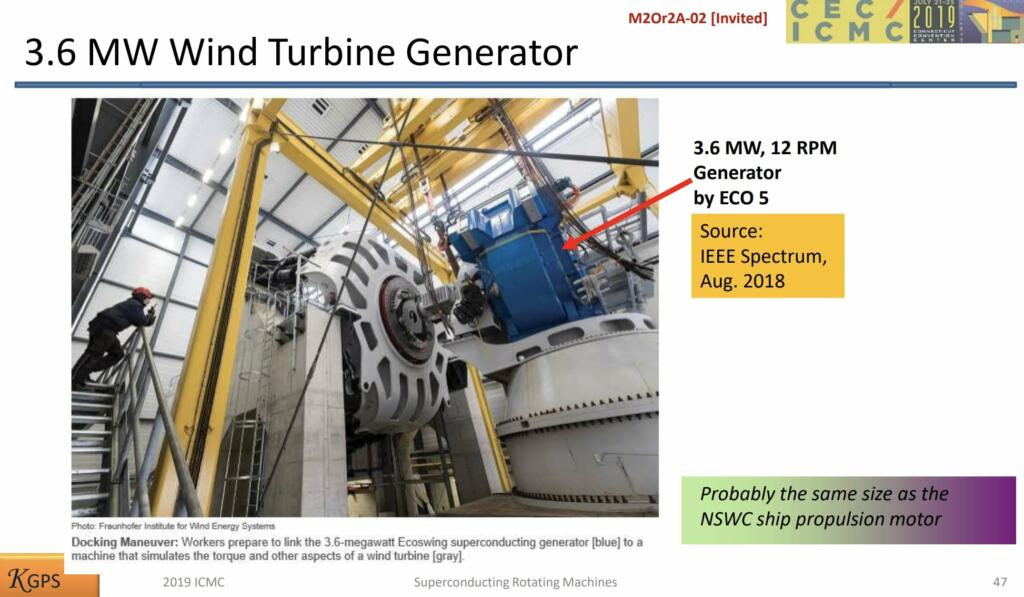

• HTS machines may have sweet applications where other technologies are not feasible; Example: Larger than 20 MW wind power generators

• An affordable and reliable HTS technology may extend its applications to central power stations, wind turbine generators, ship propulsion and industrial motors

High-temperature superconductor degaussing systems from American Superconductor (AMSC) are increasingly finding their way aboard a new class of U.S. Navy ships, designed to cloak their magnetic signatures from enemy vessels and underwater mines. Superconductors for degaussing are 50-80% lighter than conventional copper alternatives.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

If they can do superconducting magnets for those motors, why not go magnetohydrodynamic? Supposedly pretty efficient (at high Teslas) and quiet…

Power generation? As long as you use the magic word “electric,” you don’t need no stinkin’ power generation! The magic word “super-conducting” also helps you dance around the central issue of where the power for globe-spanning naval cruises will come from in the first place. Greenie magic will power all the faeries dancing in the early morning mist.

They appear to be planning to power the ships from the wind whizzing past the ship, then use that wind power to make the ship go. Perpetual motion. If you say enough magic words it really works!

Well yes, going to electric drive allows you to decouple the propellers from the long shafts leading to the power generation spaces. It’s much easier to water proof a static cable than a large rotating shaft. You can also go from propeller/rudder steering to steerable thrusters improving maneuverability, particularly at low speeds and when backing.

But what will they use for power generation? Diesels still put rhythmic noise in the water very easy for sonar to interpret. And there are so many pumps associated with conventional boilers that they have a strong sonar signature also.

“But what will they use for power generation?”

https://en.wikipedia.org/wiki/Type_212A_submarine

The diesel is primary on the 212’s. The power cells last a long time, but don’t cover the distances you find in the Pacific. Even the Atlantic is so big that even a regular transit would have them around 33% power remaining.

And since the USN doesn’t operate diesel subs – go nuclear?

That is too smart for the US Government, which is why only subs and carriers have it anymore. All the CGNs have been decommissioned.

So what do they power their current ships then?

All coming,but I fear this latest excitement, will not pan out.