NASA Ames team created and tested prefabricated voxels standardized reconfigurable building blocks. They built a set of 256 of those blocks—extremely strong 3D structures made with a carbon-fiber-reinforced polymer called StattechNN-40CF. Each block had fastening interfaces on every side that could be used to reversibly attach them to other blocks and form a strong truss structure.

* they carried 18 kilograms of building blocks in a backpack and built a boat, a tent-like shelter and bridge that could be walked on

* three robots assembled 256 voxel blocks into a shelter in 4.5 days

* the density of the material is about 1% of water

A truss structure with approximately one square meter cross section made with these voxels had an average failure load of more than 9,000 Newtons, which means it could hold more than 900 kilograms despite being incredibly light itself (its density is just 0.0103 grams per cubic centimeter). “We took these voxels out in backpacks and built a boat, a shelter, a bridge you could walk on.

The plan is to use these building blocks for orbital and moon bases.

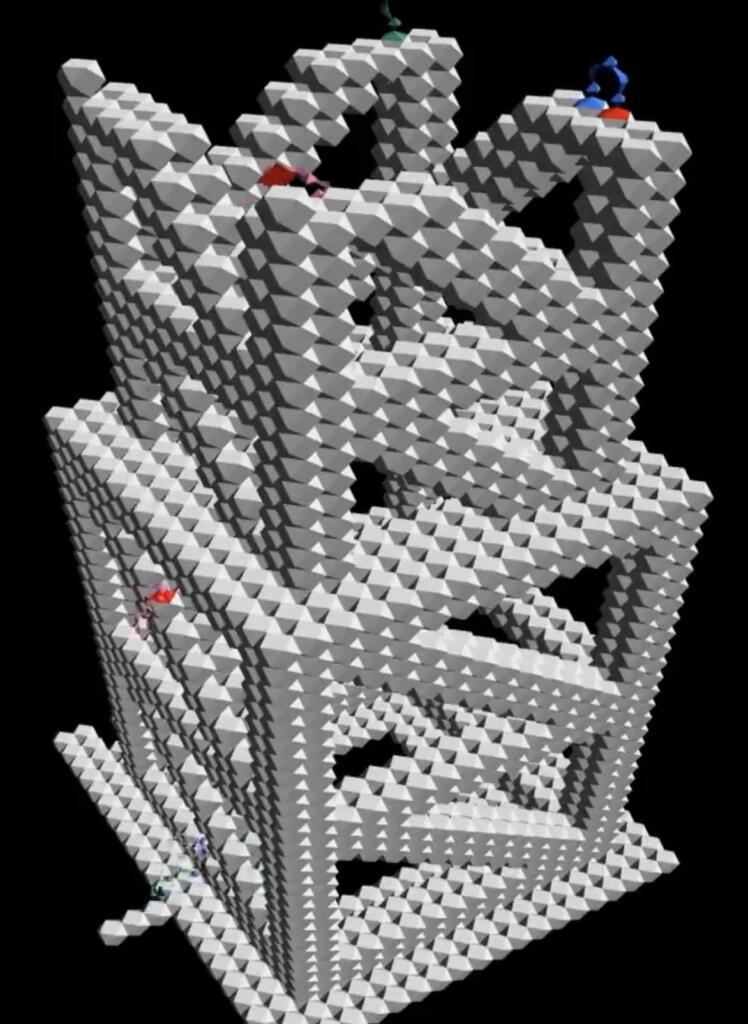

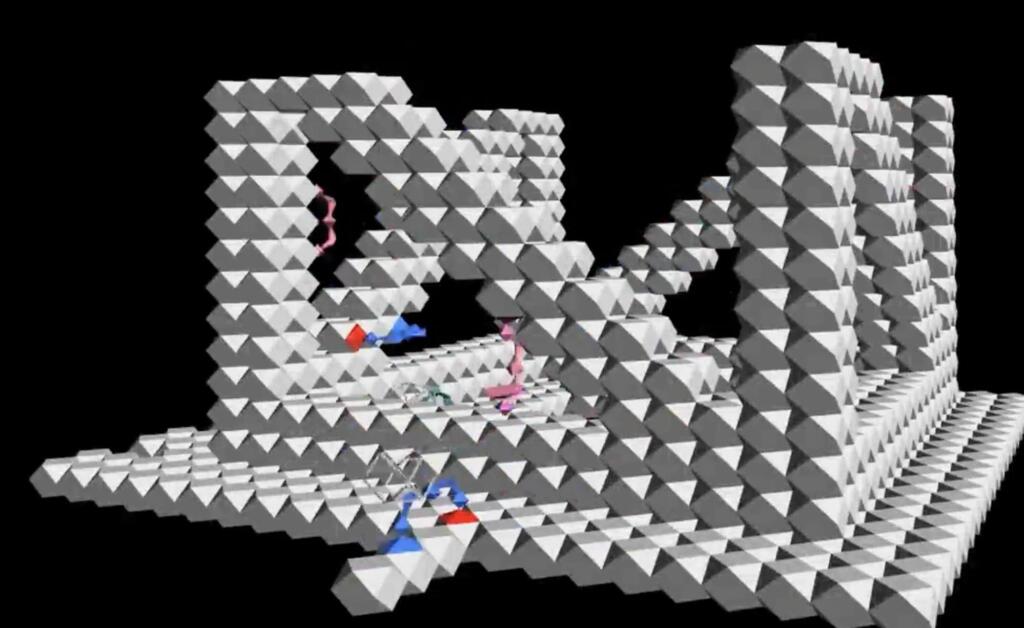

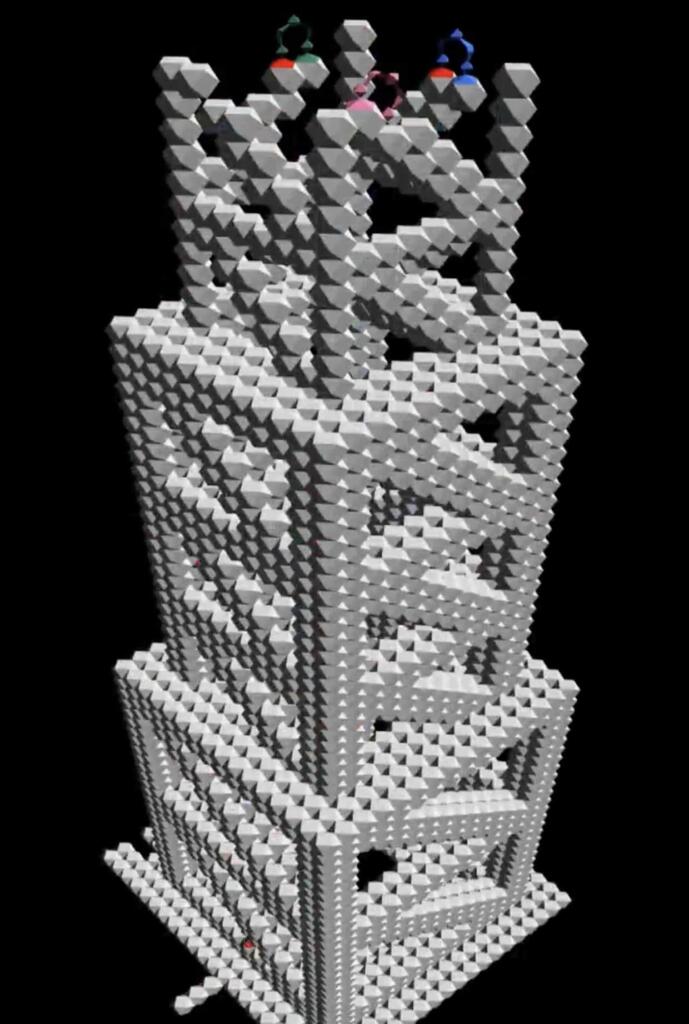

Three robots used all 256 voxels to assemble a shelter in four and a half days. The first robotic team member was a cargo handler that transported the voxels from the supply area to the right place on the structure under construction. Once there, the cargo robot handed the voxels over to a crane robot that placed them exactly where they needed to be. Finally, a fastening robot moving inside the structure attached each new voxel to the structure.

The robots oriented themselves exclusively using internal reference frames—they basically counted the voxels they stepped on. This meant no vision, no lidar, no advanced sensors or control systems.

They simulated using a dozen or so pairs of robot arms to build a skyscraper out of the metamaterial building blocks.

Above – The system consists of structural building blocks and two types of robots that can traverse, assemble, and reconfigure the blocks into various structures

Abstract

Versatile programmable materials have long been envisioned that can reconfigure themselves to adapt to changing use cases in adaptive infrastructure, space exploration, disaster response, and more. We introduce a robotic structural system as an implementation of programmable matter, with mechanical performance and scale on par with conventional high-performance materials and truss systems. Fiber-reinforced composite truss-like building blocks form strong, stiff, and lightweight lattice structures as mechanical metamaterials. Two types of mobile robots operate over the exterior surface and through the interior of the system, performing transport, placement, and reversible fastening using the intrinsic lattice periodicity for indexing and metrology. Leveraging programmable matter algorithms to achieve scalability in size and complexity, this system design enables robust collective automated assembly and reconfiguration of large structures with simple robots. We describe the system design and experimental results from a 256–unit cell assembly demonstration and lattice mechanical testing, as well as a demonstration of disassembly and reconfiguration. The assembled structural lattice material exhibits ultralight mass density (0.0103 grams per cubic centimeter) with high strength and stiffness for its weight ( 11.38 kilopascals and 1.1129 megapascals, respectively), a material performance realm appropriate for applications like space structures. With simple robots and structure, high mass-specific structural performance, and competitive throughput, this system demonstrates the potential for self-reconfiguring autonomous metamaterials for diverse applications.

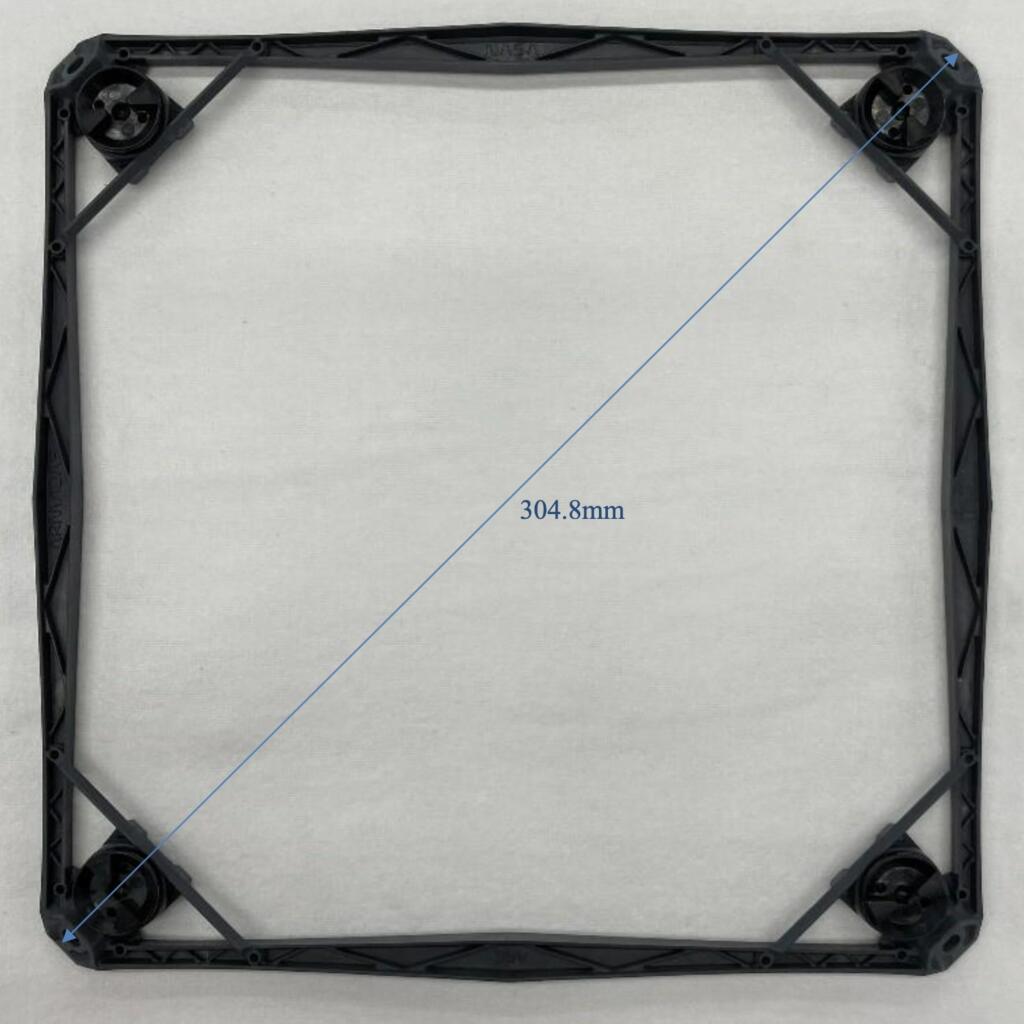

Above – Photograph of an injection molded voxel face. Six square faces are joined at the corners to form a cuboctahedron.

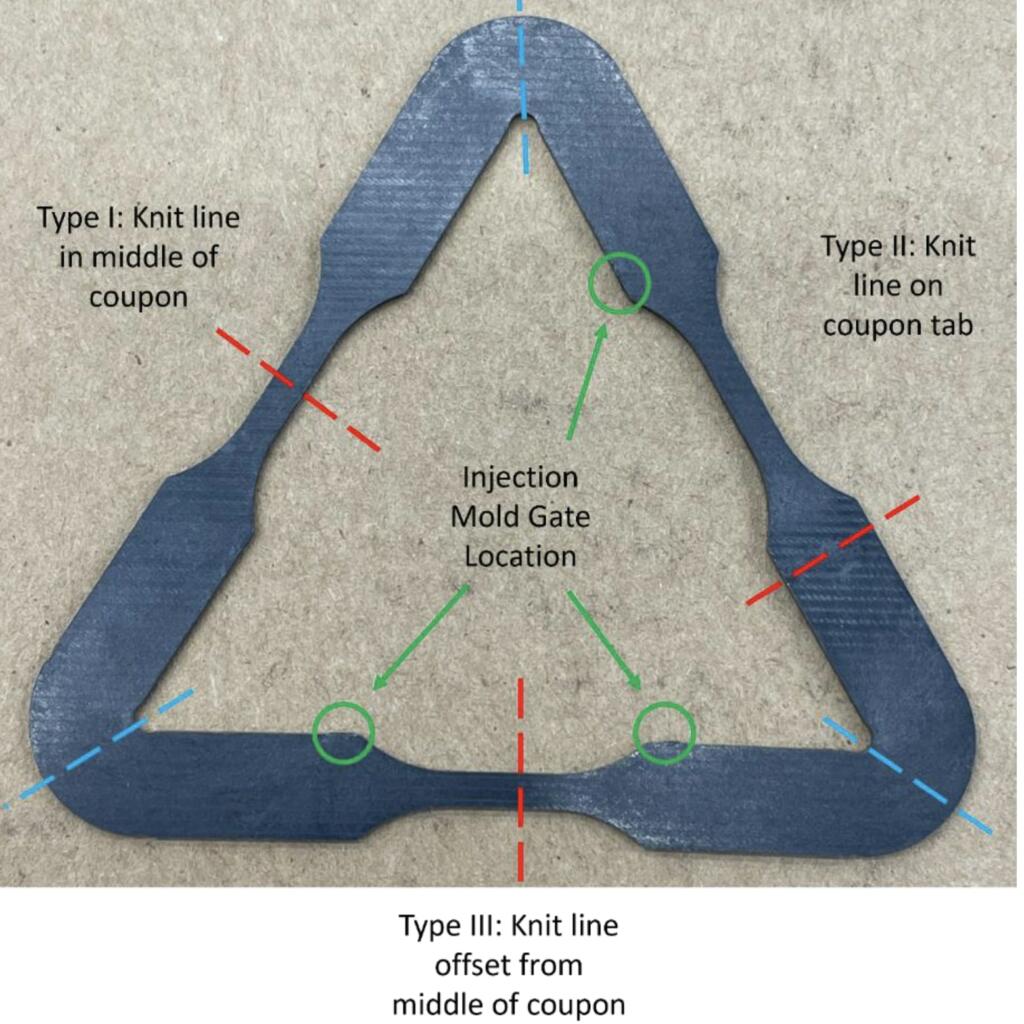

Above- Injection molded test coupons were used to test the constituent material. This injection molding part geometry yielded coupons with and without knit lines in the test region.

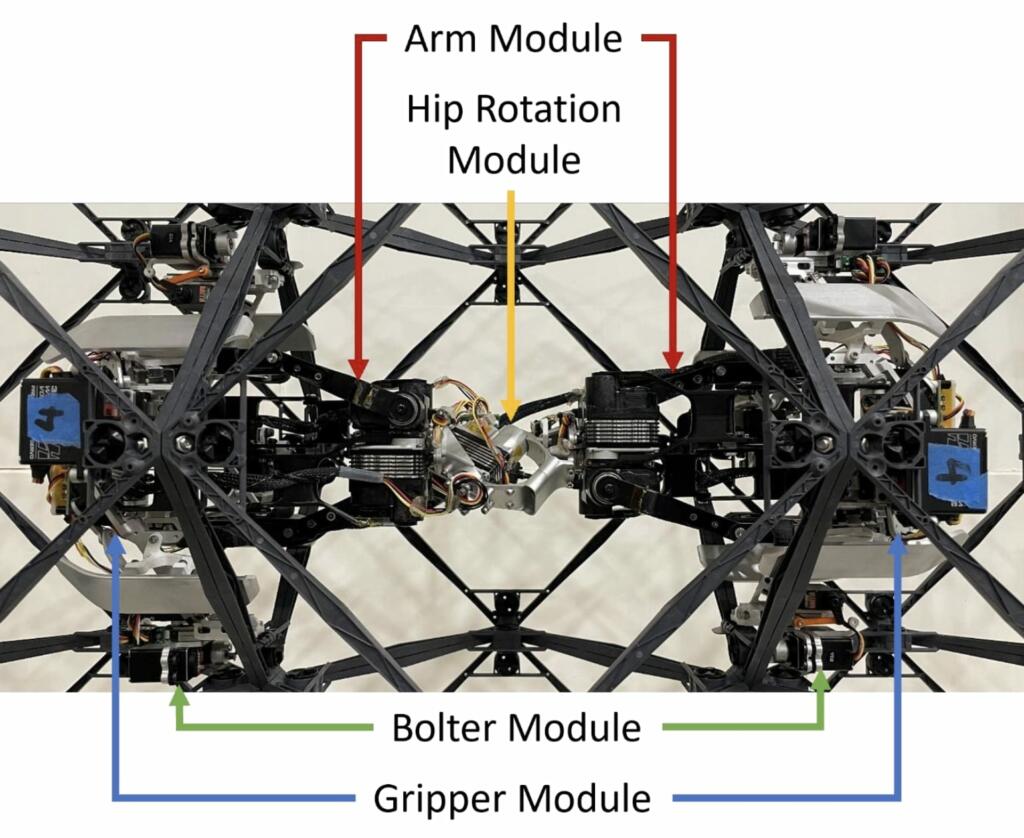

Above – MMIC-I in extended position with labeled sub-component modules.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

Prefabricated buildings, parts, and sets have been considered and attempted since the dawn of modern buildings, many score years ago. Automated builders, algorythm-ized assembly, and robotic constructo-bots almost as long. There are parts of the building that are easy to design, mobilize, and build/assemble -and- then there’s the remaining 90% of work that makes the building functional, habitable, and long-term reliable. Nothing is more complicated than a usable building – well, maybe making a life form from scratch. And certainly very few things are as difficult than doing such many-minutes-away-remotely, in hostile surrounds, and with limited back-up/ redundancy/ spares. Best to go fully functional ‘modules’ and attach. Unless you’re doing lunar adobe/ tunnels (my preference) buildings (especially habitable) should be assembled on Earth.

Self-assembling structures and machines are inevitable. Two reasons (among many more). why this is predictable. One, lower cost. Once given a template exists, w/whatever tech we have, structures, machines, buildings build themselves. Coming from a biological POV, (IMO) this is obvious. Based on my limited understanding of our current technology, not so much.

I do think we can do this current engineering to a point. I see in the near future (no I’m not psychic I’m just making projected assumptions). We’ve been using chemical reactions to change physical materials for a very, very long time. It’s a “creative agent” of our early industrial revolution, and we’ve also been that for thousands of years. Biology as a change agent has also been known for 1k++ years. (Know the basics of making beer?)

I truly believe that we need to construct habitats for humans to live long term off Earth. Starting going back the moon, staying there and mining it’s resources. To use asteroids for the same objective. To build amazing, climate controlled colonies the size of our current cities, but say in space, we’re going to need VAST raw materials. And the ability to build stuff that’s dangerous for people to be directly “there”.

Want to live on Mars? Great, but lets start w/going back to the moon and staying there. It’s only 3days from Earth using 1960’s technologies “slow boats”. Oh, the 2nd reason: Because we can.

Self-assembling structures and machines are inevitable. Two reasons (among many more). why this is predictable. One, lower cost. Once given a template exists, w/whatever tech we have, structures, machines, buildings build themselves. Coming from a biological POV, (IMO) this is obvious. Based on my limited understanding of our current technology, not so much.

I do think we can do this current engineering to a point. I see in the near future (no I’m not psychic I’m just making projected assumptions). We’ve been using chemical reactions to change physical materials for a very, very long time. It’s a “creative agent” of our early industrial revolution, and we’ve also been that for thousands of years. Biology as a change agent has also been known for 1k++ years. (Know the basics of making beer?)

I truly believe that we need to construct habitats for humans to live long term off Earth. Starting going back the moon, staying there and mining it’s resources. To use asteroids for the same objective. To build amazing, climate controlled colonies the size of our current cities, but say in space, we’re going to need VAST raw materials. And the ability to build stuff that’s dangerous for people to be directly “there”.

Want to live on Mars? Great, but lets start w/going back to the moon and staying there. It’s only 3days from Earth using 1960’s technologies “slow boats”.

Seastead?