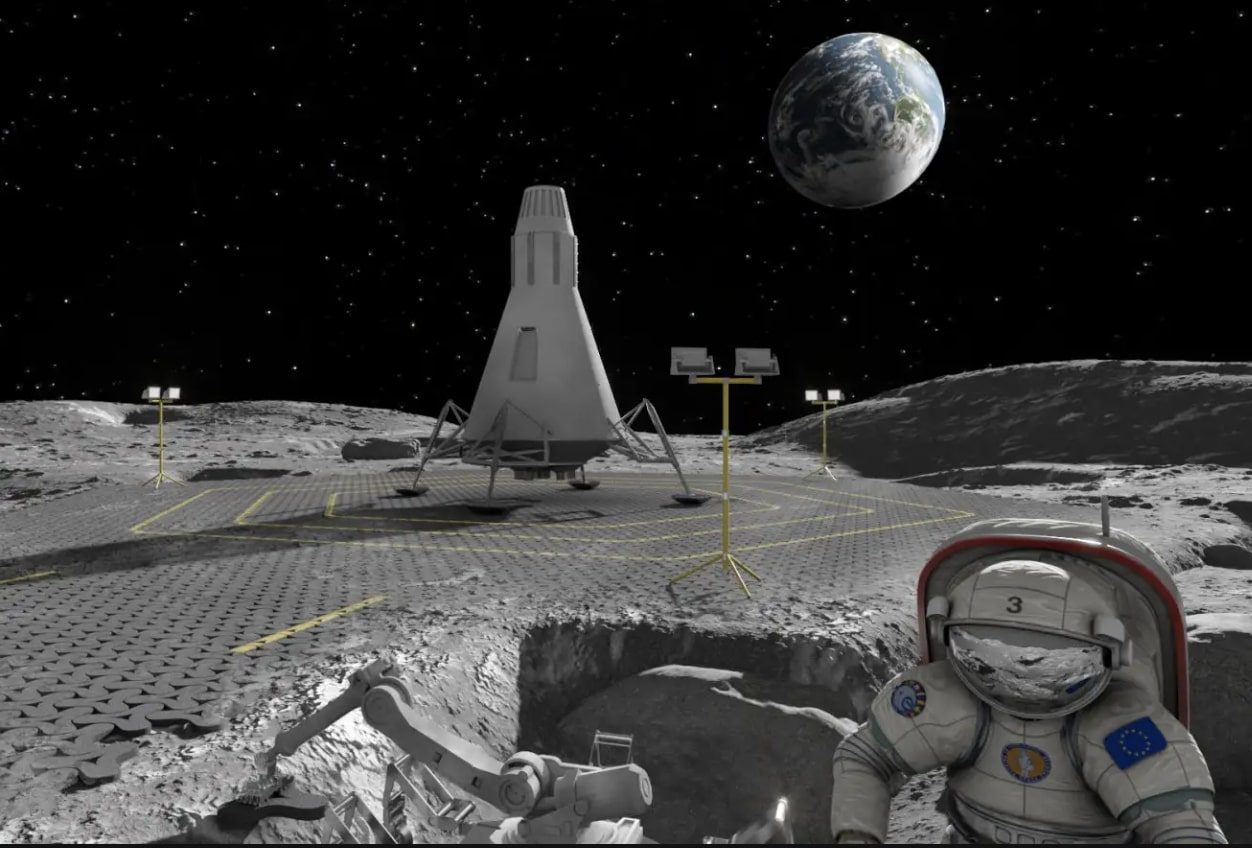

The suspended dust generated when lunar rovers move across the lunar soil is a significant risk for lunar missions as it can affect the systems of the exploration vehicles. One solution to mitigate this problem is the construction of roads and landing pads on the Moon. 12 kilowatt laser(s) have melted simulated regolith in the lab as a proof of concept to melt regolith for roads.

A lens of approximately 2.37 meters squared would need to be transported from Earth to act as a sunlight concentrator in place of the laser. Using a Fresnel lens as a light concentrator and considering the required power (188 W/cm2) and the spot area (0.16 meter square with a spot diameter of 45 mm) for the fabrication of the interlocking elements, this would translate into a lens of approximately 2.37 square meters (considering a solar flux on the Moon of approximately 1400 W/m235 and an efficiency of the lens of 90%). The relatively small size of the required equipment and the simplicity of the system would be an advantage for the use of this technology in future missions on the Moon.

In-situ resource utilization (ISRU) techniques must also be developed. Concentrated light for paving on the Moon by melting the lunar regolith was investigated. A high-power CO2 laser is used in the experiments. With this set-up, a maximum laser spot diameter of 100 mm can be achieved, which translates in high thicknesses of the consolidated layers. Furthermore, the lunar regolith simulant EAC-1A is used as a substitute of the actual lunar soil. At the end of the study, large samples (approximately 250 × 250 mm) with interlocking capabilities were fabricated by melting the lunar simulant with the laser directly on the powder bed. Large areas of lunar soil can be covered with these samples and serve as roads and landing pads, decreasing the propagation of lunar dust. These manufactured samples were analysed regarding their mineralogical composition, internal structure and mechanical properties.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

The real question is, can you sinter landing pads in place, or do you build up bricks and use a robot arm as a bricklayer?

All the talk of making roads and 3D printing seem a bit foolish to me.

Granted, the technology may be used.

But for the most part I see any harsh environment in space being underground.

Additive printing of doors for large excavated caverns seems to be the direction I think they should be focused on.

And the technology to convert natural open underground structures into livable spaces where people have a good quality of life.

Agreed. More of a widepsread burrow with signficant underground circulating infrastructure of tunnels and passages – possibly including use of a modified Boring tool for 100s of miles or heaven-forfend–hyperloop with several observation, launch, and access verticals. Elon should get in on this and take over a couple of square miles to build his first colony – likely the only off-world existence he will enjoy before death or age-extended near-death.

Cool.

Regolith, kicked up by tires of passing rovers, falls back to Luna at the SAME RATE as gravel or boulders. No air.

Speaking of which, how about those tires?

Whether the lunar surface excess loose dust problem is “solved” by melting it with big Fresnel lenses or not, I think the real problem is that all particles of lunar regolith are hideously abrasive: like freshly ground glass. There’s been no weathering on Luna to soften all those uncountable edges. They’re HELL on tires.

On tires, on bearings, on sliding parts. Hêll on hinges, door seals, hatch clamps and almost all moving -and- touching parts. No air. No weathering.

So, back to the tires. I’m going to bet that THE big industry that has to get going at its earliest (apart of course for “making air to breathe” and “water to drink” and yah, “replacement fuel to GO HOME after this shît”), will be local manufacturing of new tires. Maybe just retreads, but still … going to need a LOT of those retreads.

And you cannot build ’em out of regolith!

Hmmm… no?

Maybe we could! If the wheels and “tires” were more like Roman cartwheels, you know, before the discovery of rubber and then pneumatic inflation for tires, but hard inflexible (strong!) wheelie things, maybe they’d be the long term, extended range option.

After all, somehow or another, my Californian ancestors from 175 years ago lurched and trundled across the freaking Sierra Nevada mountain range, on rigid wheels, on wooden carts, pulled by oxen or horses, mules or donkeys. We’re not talking high tech. 4,000 years of rigid wheels have a History, you know!

And those rigid wheels ought to be manufacture-able by melting regolith. Make high tensile strength fibers. There are your basic building blocks. Adhere them together with Earth-made (early on, later maybe Luna made) plastics. Epoxies or other plastics that have a lot of springy give but ultimately are outstanding binders too. Greenpeace or the EPA though might get their knickers in a twist over the “Lunar Pollution” of bringing thousands or millions of tons of non Lunar plastics and critical raw materials to Luna, just to “wear them out” to dust, scattering it everywhere.

Ummm… First World problem.

So, cartwheels! Man these’d be real Steampunk rollers. Huge cartwheels, all covered in stuck-on regolith, rolling like run-away watermills over the Moon’s surface. Make them intentionally “regolith sticky” so as to build up an ever-replaceable tread, which crumbles off all the time, but then also builds back up by compression too. The dustiest, ugliest, totally steampunk wheels. Turn a BUG into a FEATURE!

I’m so off topic its laughable.

But still … melting tiles worth of simulated lunar regolith with either CO₂ lasers or big Fresnel bug-burning lenses? Really?

Harrumph!!!

⋅-⋅-⋅ Just saying, ⋅-⋅-⋅

⋅-=≡ GoatGuy ✓ ≡=-⋅

“Regolith, kicked up by tires of passing rovers, falls back to Luna at the SAME RATE as gravel or boulders. No air.”

There’s actually a problem on the Moon of electrostatically levitated dust. Direct exposure to sunlight causes the dust on the surface to become electrostatically charged thanks to the photo-electric effect, with no air to discharge it.

Even short of actual levitation, the finest particles won’t fall as fast as the rubble. At least during the day, and for a while after.

Yes, I sort-of remember that.

But IF so, then it brings up ‘the other problem’. Which is that the same electrostatic fine-sorts lofting isn’t exactly going to be normal to the plane of Luna’s surface (i.e. ‘up and down exclusively’). Nope. More like a cloud. All directions. As electrostatic forces are known to be.

So, you ‘pave a road’ with beautiful just-made vitrified tiles of regolith. Regotiles? Tileliths? Anyway, off to the side of the road is nekkid regolith. And sunlight. So, the probably-thin clouds of itty-bitty-bits comes a’calling. And starts to coat the brand new road with more dust.

Oh, drat!

Being a scientist-of-sorts, my immediate question is, “well what’s the deposition rate?”

Are we talking millimeters per millennium or centimeters a year? How does it vary depending on particular spot on Luna where we’re measuring the rate? Does it have a season or seasonal component? Don’t laugh! Could have, for all we know.

The answers to these in turn determine whether all the vitrified roadway business is a load of hogwash, or a good solution in the reasonable term. If µm a day, then vitrification is good stuff in theory. If centimeters a year, then it is hopeless. Have to learn to deal with the ‘shifting sands’ of Luna.

⋅-⋅-⋅ Just saying, ⋅-⋅-⋅

⋅-=≡ GoatGuy ✓ ≡=-⋅

I would suppose that the way to deal with this would be to electrostatically manipulate the dust. Perhaps you could sputter in some additive that would produce a higher positive voltage on the road, or have negatively charged curbs that would ground the dust. (In more than one way.) Maybe both.

I recall at one time there was a proposal to use a particle accelerator to charge the Moon to the point where you could land and take off using charged balloons. Lunar zeppelins, as it were. The energy cost actually seemed feasible.

Had to be given up when they realized how much of the surface dust they’d be lifting in the process; It would have been a real sandstorm.

Maybe this:

You’ll dot the sides of the road with lamp posts which also have a positive charge at their bulbous top. Spherical shape or optimized.

Far away from the road you have a second parallel set of poles with a negative charge.

Particles of opposite charge now approach each other, in the middle of these two parallel sets of poles, and neutralize the charges.

Because of slight differences in ballistics, once neutralized, you’ll get fractionation by particle size and weight, which might have uses.

This will not be a complete solution. So, dust trying to collect on either set of poles can be further neutralized by equipping each of the poles with an opposite polarity repurposed ion-engine. The particles either find their way into a collection receptacle or thrust downwards into a berm. You wouldn’t want to thrust it into any vector that could dust op other settlement sites.

I guess cathode producers might like this market.

You could sinter lunar regolith studs for studded tires I suppose…

Mike Turner proposed melting lunar regolith to produce basalt fiber which is extremely strong and can serve as a thermal barrier shield. https://casi.ca/resources/Documents/ASTRO/2018/Papers%20Submitted/2A-2%20A%20Rotating%20Tapered%20Balanced%20Sling%20Launcher%20on%20the%20Moon%20Made%20of%20Lunar%20Regolith%20Basalt%20Fiber.pdf

The USSR used basalt fiber to fabricate ICBM nose cones. Basalt fiber has been used to reinforce military helicopter fuel tanks and has been proposed as a micrometeorite shielding material for satellites. At scale basalt fiber could be a significant material for construction of space habitats and other large orbital structures. Basalts in regolith are more prevalent in equatorial regions. Highland regions have another potentially useful material called anorthosite which can be melted to produce e-glass, which does not have the thermal barrier properties of basalt fiber but whose production process would be similar to basalt fiber and which can be used in applications similar to those on Earth.

Aachen University’s Institute of textile technology has done some work on production of basalt fiber from lunar regolith simulant. In 2018 I developed a proposal to the EU Horizon 2020 program that involved Aachen, University of Latvia, Riga Technical University and Yuzhnoye Design bureau in Ukraine. We were working on two different approaches to the development of basalt fiber from lunar regoliths. The project did not get funded then, but I remain convinced that it is a promising approach for the development of lunar resources.

I guess that the production of basalt fibers would present no risk to health (or at any rate, no higher risk to health than regular regolith) since it would be automated? Whenever I hear about basalt fibers, I cannot help but remember natural rock fibers, the mining and use of which is progressively being banned in more and more jurisdictions as a carcinogenic.

Take this one step further, you could use it to print 3D structures one layer of lunar dust at a time.

Level an area and separate removed material into 2 piles, Rocks and lunar dust. Then use a laser or computer controlled mirrors to print one layer. Spread another layer of lunar dust and repeat with the laser. This is effectively is a 3D laster printer Covered storage areas could be printed and then the unmelted dust could be removed. Or you cold trip a large block with internal tunnels and rooms After all the dust is removed metal airlocks be be installed. the walls or melted rock can have a layer of sealant applied to prevent air leaks. And then the interior could be filled with air and life support installed.

https://www.pcmag.com/news/company-that-3d-prints-houses-on-earth-lands-lunar-construction-contract

This is what several companies are doing. There is a NASA contract for it.