The Team Project “Solutions for Construction of a Lunar Base” was the product of 9 intense weeks of collaboration during the Space Studies Program 2021 – Strasbourg, at the International Space University.

I had written about their concept to lay a SpaceX Starship flat on the moon to start a moonbase. I did not know the source of the graphic until now.

There is a well-established and researched idea of utilizing the large volume and properties of empty fuel tanks to create robust space habitats. This was applied on Skylab, and has been proposed for various rocket stages such as the external tanks on the Space Shuttle. While this is applicable to any sufficiently large rocket body, after surveying the current state-of-the-art launchers and what bodies can be delivered to the lunar surface, the most mature concept was using the SpaceX Starship Human Landing System (HLS) as a structural basis for the lunar settlement, (see above). The reported capabilities, low cost, massive volume, and high mass capacity means that a larger and more capable habitat can be delivered and constructed on the lunar surface, more so than any other concept achievable within the next decade. The concept is to decommission a Starship HLS and transform it into a permanent base while using its entire internal volume, including the fuel tanks, as a habitat.

The additional volume provided by the conversion of the fuel tanks means there is great potential for renting out this space to other entities to generate revenue and promote sustainability and growth. This plan relies mostly on existing technologies and limited modifications to the vehicle, including using a series of rovers, MOdular RObotic Construction Autonomous System (MOROCAS), for the purpose of setting up equipment to horizontalize the lander on its side. Additionally, they will aid in setting up surface infrastructure and stacking regolith on top of the base for crew protection. This makes the Rosas Base solutions incredibly viable for the construction of a lunar base in the near future.

The plan to transform an active vehicle to a large, habitable volume requires a series of technical steps. To assist in this operation, the MOROCAS fleet will be developed and utilized in the transportation sequence

• Starship (SS) Rosas is the first lander to launch and arrive prior to the crewed lander. It is uncrewed and stocked with equipment and supplies to support humans at the base site of the south pole of the Moon. This will later become the permanent base for the incoming crew.

• The crewed SS 501 will follow and land at a safe distance away from SS Rosas.

• The crew will remotely operate the MOROCAS rover fleet from SS 501 for the purpose of deploying power reactors, solar panels, and radiators, as well as drain remaining fuel into their respective tanks.

• The MOROCAS will install a system that will assist crew to horizontalize the SS Rosas on the ground.

• Some crew members will conduct their first LEVA to initiate the horizontal maneuver of the SS Rosas, thus becoming Rosas Base. This is referred to as Groundbreaking Day.

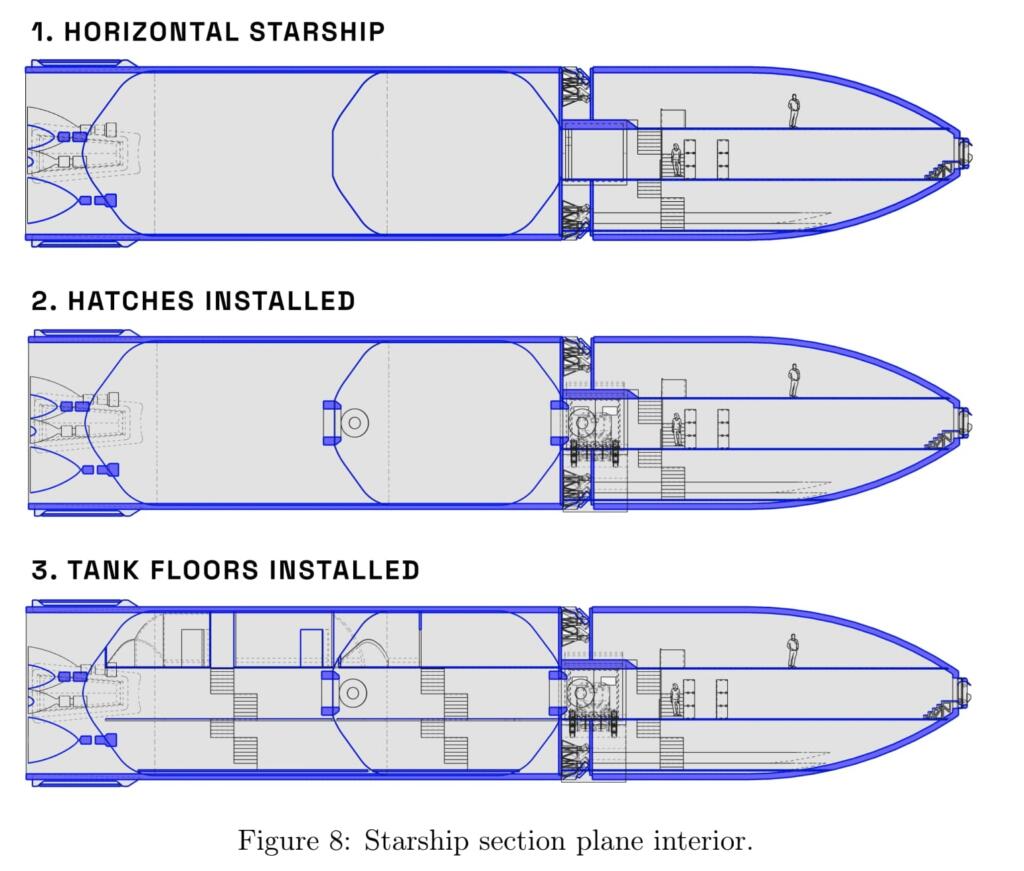

• The crew will install floors, walls, lights, bathrooms, life support systems, ventilation, water tanks, beds, and any other equipment that the habitat requires.

• The volumes will be occupied with their intended equipment, whether this is laboratory equipment, agriculture area, gym, lounge, or infirmary. After completion of the horizontal procedures, the remaining crew members will depart SS 501 and arrive at Rosas Base where they will spend the remainder of the mission.

Rosas Base will be continuously inhabited by crews arriving on visiting landers. Provisions for expansion of the base will also be made so that future modules can be attached to the nose interface of Rosas Base.

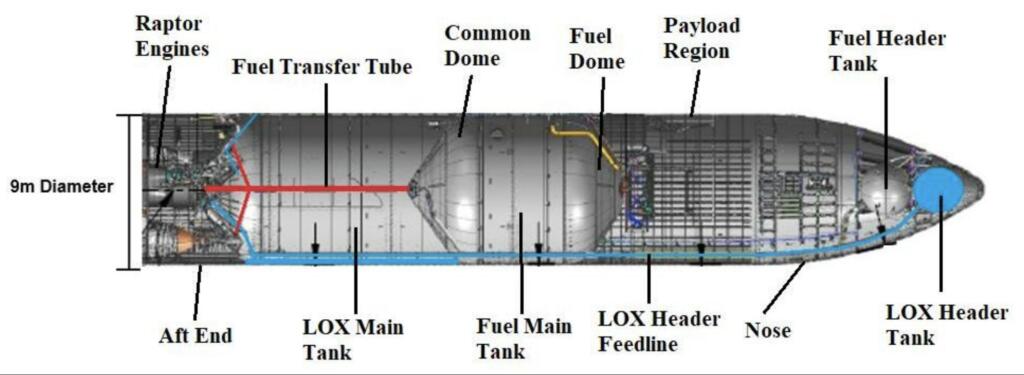

SpaceX’s Starship is reported that it can carry up to 200-300 metric tons of mass to the lunar surface (expendable mode) inside an 1100 cubic meters payload fairing. The assumption of the team is that there is a limitation of 100 tons of useful payload. The Starship uses methane and oxygen stored in two large tanks which are estimated at 600 cubic meters and 800 cubic metersrespectively. These volumes will be transformed into habitable volumes. The bay will need to be modified on Earth prior to the launch with the mounting of rigid supports that will be used as a skeleton for additional interior structures and fittings. This is done to minimize the workload of crew on the Moon. The interior of the Starship will be divided into three equal-height floors connected by stairs.

The original Space X Starship concept design proposes two airlocks, both provided with cable-suspended elevators used for payload deployment. One of the Starship airlocks will be modified to include a retractable corridor that can be extended up to 5 m away from the main body of the base. This corridor can then be covered by regolith to protect the crew against radiation and micro-meteorites impacts. The second airlock will be re-purposed into an extended observation deck which allows the crew to see their surroundings as well as the Earth.

A collection of tools, designed to interface with the MOROCAS, will be developed to perform various tasks, such as:

• De-tanker and external bladders (A). The MOROCAS will use the de-tanker to connect to the refuelling ports of the fuel tanks and transfer all the excess oxygen and methane to the external bladders. This contraption will also be used to fill the fuel tanks in the payload volume with air at a later stage. The de-tanker will also drain the water tanks in the payload volume to lighten the load on the vehicle while it is being tipped. This water will be restored in the tanks following the horizontal operations.

• Regolith moving system (B). This module will be used to pile regolith into berms as part of the Dep-Ops and to cover the whole station with regolith at the final stage in the construction.

• Drill and anchors (C). This module will be used to fix several anchors in the ground as part of Dep-Ops.

• Hinge (D). This large contraption is part of the equipment that is used for tipping the Starship and will be deployed during Dep-Ops. This will be connected firmly to the bottom of the SS Rosas and to the anchors installed underneath.

• Scissor lift (E). This device will support the body of the Starship from underneath while this is being lowered into its final horizontal configuration.This device will be required to carry a substantial load during the horizontal operations.

• Crewed rover (F). This rover will be used by the crew to travel from SS 501 to SS Rosas during the construction activities. The rover will be pressurized and able to act as a temporary habitat for all future LEVAss. It will need to fit as a whole system through the airlock of the base and have an interface with the LEVAs suits in order to make these accessible to the crew while inside the rover.

Brian Wang is a Futurist Thought Leader and a popular Science blogger with 1 million readers per month. His blog Nextbigfuture.com is ranked #1 Science News Blog. It covers many disruptive technology and trends including Space, Robotics, Artificial Intelligence, Medicine, Anti-aging Biotechnology, and Nanotechnology.

Known for identifying cutting edge technologies, he is currently a Co-Founder of a startup and fundraiser for high potential early-stage companies. He is the Head of Research for Allocations for deep technology investments and an Angel Investor at Space Angels.

A frequent speaker at corporations, he has been a TEDx speaker, a Singularity University speaker and guest at numerous interviews for radio and podcasts. He is open to public speaking and advising engagements.

The regolith has challenging electrostatic and abrasive characteristics, there will be rapid need for a ‘garage’ for maintenance and separation of the outside regolith environment from the machinery wherever possible. it may be desirable to use some of the fuel tank space for this purpose.

Teslabot is really the key here, both in autonomous mode for simpler tasks and in a robust remote mode (perhaps with AI assist) so humans can work in shirt-sleeves without the constant pressure of an inflated suit interfering with their motions.

Seems to me Starship could be modified to land horizontally like the ships in the Tv series Space 1999 which Musk is a fan . The starship “house” should be modified as much as possible on Earth before the moon trip. There is no reason SpaceX could not modify the interior of the tanks on earth with pressure locks and other structures for human occupancy.

The idea of working on major projects like this in pressure suits on the moon seems like not the best use of labor.

Instead, erect a prefab pressurized “garage” on the Moon that is big enough for a starship. Do your major work in shirt sleeve conditions. When the build or manufacturing is complete, roll it out from the garage for it’s intended use.

After all, most manufacturing of things on Earth takes place indoors.

Or, just use Optimus Tesla bot.

That vertical to horizontal huge rocket stand position change has to be rehearsed first on Earth. If it works, then try it on the Moon by remote control. Otherwise, the maneuver is too risky and dangerous or a total disaster.

While I don’t love the idea of tipping them over on the moon, and slicing them up, I am super excited on how the Starship will truly open up the moon…and space in general.

I would design some of them to basically be permanent buildings on the moon, and then others that are just for cargo, where the top opens up, and using a crane can unload a inflatable building, built on Earth, so they just place it where they want it, hook up some hoses, and begin inflating. So many cool designs will emerge once Starship has proven itself to be a reliable work horse.